42BLDC

Holry

| Power: | |

|---|---|

| Availability: | |

| Quantity: | |

Product Description

Adapt to harsh environment, cost-effective, high efficiency, energy saving and environmental protection, efficiency above 80%; High-performance rare earth permanent magnet rotor, high torque, low inertia, and good dynamic response; Three-phase sine wave design, with excellent low-speed smoothing characteristics; Low noise, maintenance-free, and long service life;

low interference:

The brushless motor removes the brush. The most direct change is that no spark is generated when the brush motor is running, which greatly reduces the interference of the spark to the remote control radio equipment.

Low noise and stable operation:

The brushless motor has no brush, the friction is greatly reduced during operation, the operation is stable, and the noise is much lower. This advantage is a huge support for model stability.

The wear of brushless and brushless motors is mainly on the bearings. From a mechanical point of view, a brushless motor is almost a maintenance-free motor. When necessary, just do some dust removal.

Personal Use Products – Several personal use products also rely on a high-quality 24-volt DC motor. Examples of these include home copy/printer machine, hair dryer, footbath, and stick massager.

We can provide and support the models you need. We have brushless models of different models and powers. Welcome to consult!

Technique Parameter

| Model | 42BLDC41-20340-05B24 | 42BLDC61-20540-05B24 | 42BLDC81-20840-05B24 | 42BLDC96-21040-05B24 |

| Number of Poles | 8 | 8 | 8 | 8 |

| Number of Phases | 3 | 3 | 3 | 3 |

| Nominal voltage VDC | 24 | 24 | 24 | 24 |

| Rated speed RPM | 4000 | 4000 | 4000 | 4000 |

| Rated Torque N-m | 0.0625 | 0.125 | 0.185 | 0.25 |

| Rated Current Amps | 1.8 | 3.5 | 5.2 | 6.6 |

| Output Power Watts | 26 | 52 | 78 | 105 |

| Peak Torque N-m | 0.18 | 0.38 | 0.55 | 0.75 |

| Peak Current Amps | 5.4 | 10.5 | 15.6 | 20 |

| Torque constant N-m/A | 0.035 | 0.036 | 0.036 | 0.0376 |

| Back EMF V/k RPM | 2.45 | 2.71 | 2.74 | 2.62 |

| Rotor inertia kg·cm2 | 24 | 48 | 72 | 96 |

| Body Length(L)mm | 41 | 61 | 81 | 100 |

| Weight kg | 0.33 | 0.45 | 0.65 | 0.8 |

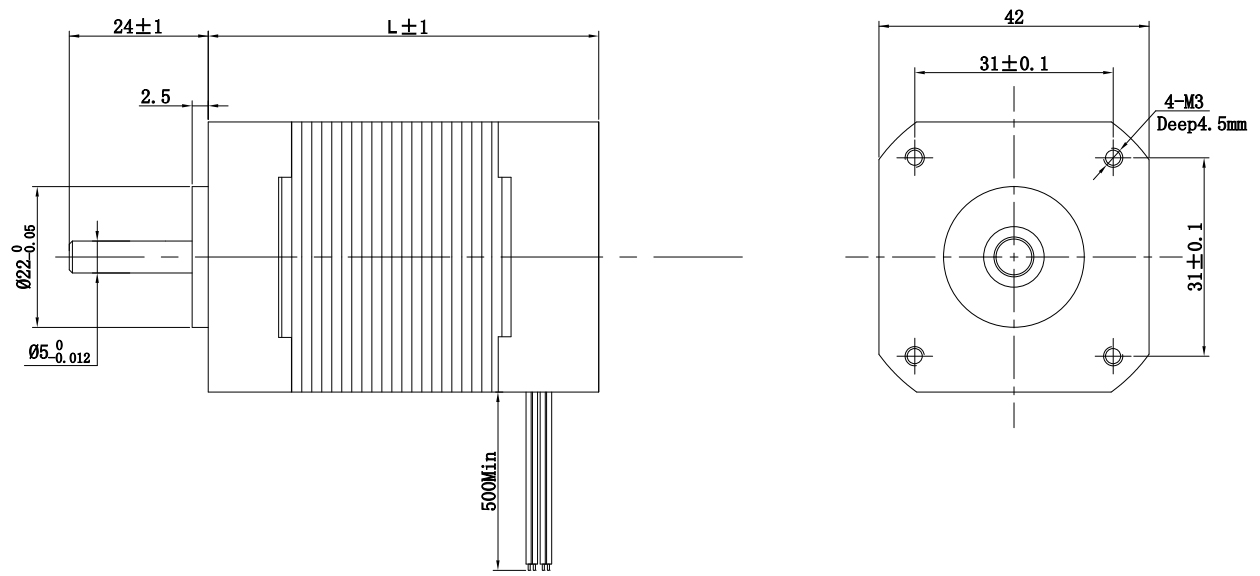

Shaft out method

Video

FAQ

Among these, brushless DC motors (BLDC) feature high efficiency and excellent controllability, and are widely used in many applications. The BLDC motor has power-saving advantages relative to other motor types.

Although the brushless motor was invented in the mid 19th century, it wasn’t until 1962 that it became commercially viable. What is a brushless motor? Brushless motors are synchronous electric motors that move around electronically.

They contain minimal parts such as the commutator, rotary parts and slip rings that contribute to increasing its weight. The brushless motors also dominate several applications such as hard drives, pumps, fans, coffee machines, hair dryers, mixers and CD/DVD players in variable and adjustable speed applications.

content is empty!