CNC spindle motors are an essential component of computer numerical control (CNC) machines. These motors are responsible for driving the cutting tools that shape and form various materials to meet specific design requirements. In this article, we'll cover everything you need to know about CNC spindle motors.

What Are CNC Spindle Motors?

CNC spindle motors are electric motors that are designed to drive the spindle of a CNC machine. The spindle is the part of the machine that holds the cutting tool and rotates it at high speeds. CNC spindle motors are typically high-speed motors that are capable of rotating the spindle at speeds of up to 24,000 RPM.

CNC spindle motors are high-speed electric motors that are used to power the spindle of a CNC (Computer Numerical Control) machine. The spindle is the rotating component of the machine that holds the cutting tool, and it is responsible for rotating the tool at high speeds to perform various machining operations, such as drilling, milling, and cutting.

CNC spindle motors are designed to provide high torque and high speed, and they are usually controlled by a variable frequency drive (VFD) to adjust their speed and power output. They come in various sizes, power ratings, and types, including air-cooled and water-cooled spindle motors.

Types of CNC Spindle Motors

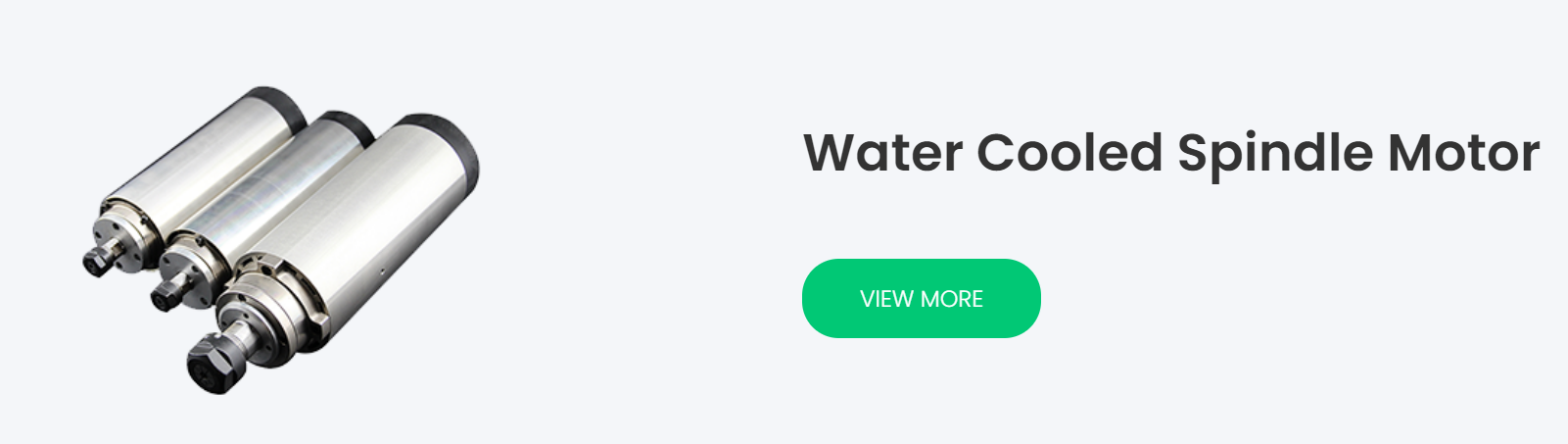

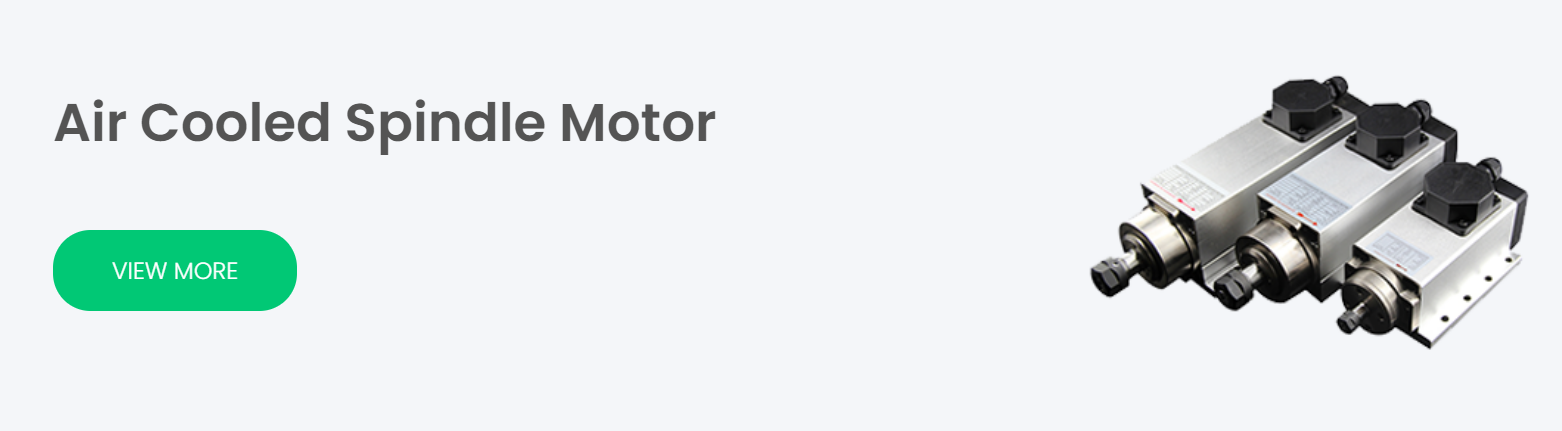

There are two main types of CNC spindle motors: AC and DC. AC spindle motors are more common and are used in most CNC machines. DC spindle motors, on the other hand, are used in specialized CNC machines that require high torque at low speeds. Of course, we can also be divided into the following categories:water cooled spindle motor, air cooled spindle motor, CNC ATC spindle motor and VFD CNC spindle motor.

Video of cnc spindle motors

Features of CNC Spindle Motors

CNC spindle motors come with various features that affect their performance, reliability, and ease of use. Some of the most important features to consider when choosing a spindle motor for your CNC machine are:

1、Power rating

The power rating of a spindle motor determines its cutting force and speed. Higher power ratings are suitable for heavy-duty machining, while lower power ratings are ideal for light-duty and precision machining.

2、Speed range

The speed range of a spindle motor determines the maximum and minimum speeds at which it can operate. A wider speed range allows for more flexibility and versatility in machining operations.

3、Cooling method

The cooling method of a spindle motor affects its temperature stability, noise level, and maintenance requirements. Liquid-cooled motors provide better cooling performance but require more maintenance, while air-cooled motors are easier to maintain but may generate more noise and heat.

4、Bearing type

The bearing type of a spindle motor determines its radial and axial stiffness, which affects its cutting accuracy and tool life. Ceramic bearings provide higher stiffness and durability than steel bearings but are more expensive.

5、Control system

The control system of a spindle motor determines its speed and torque accuracy, as well as its response time and dynamic performance. A high-quality control system ensures smooth and precise machining operations.

Applications of CNC Spindle Motors

1、Metalworking

CNC spindle motors are used in metalworking applications, such as milling, turning, drilling, and grinding, to produce complex and precise metal parts for various industries, such as aerospace, automotive, and medical.

2、Woodworking

CNC spindle motors are used in woodworking applications, such as routing, carving, and cutting, to produce intricate and decorative wood products, such as furniture, cabinets, and musical instruments.

3、3D printing

CNC spindle motors are used in 3D printing applications, such as laser sintering and fused deposition modeling, to produce functional and durable 3D-printed parts for various industries, such as prototyping, engineering, and medical.

Metalworking

Woodworking

Woodworking

3D printing

Conclusion

CNC spindle motors are critical components of modern manufacturing and machining processes that require high precision, efficiency, and flexibility. By understanding the types, you can choose the right motor for your CNC machine and achieve the best results in your machining operations. Whether you're working with metal, wood, plastic, composites, or 3D printing, a reliable and high-performance CNC spindle motor can make all the difference in your productivity and success.

Our main products include stepper motors, brushless motors, servo motors, etc. If you have related needs, you can also contact us for more information. You can trust us 100%. We have our own factory and will Provide you with the most professional technical support and professional team consultants.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు

Woodworking

Woodworking