- All

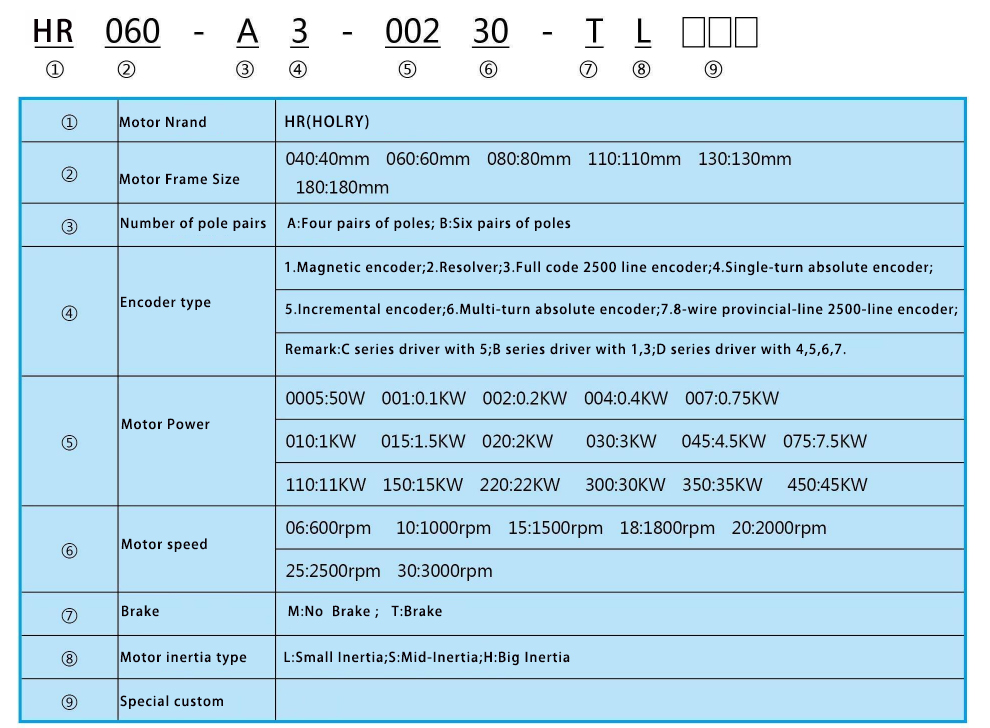

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

-

English

-

Русский

-

العربية

-

Français

-

Español

-

Português

-

Deutsch

-

italiano

-

日本語

-

한국어

-

Nederlands

-

Tiếng Việt

-

ไทย

-

Polski

-

Türkçe

-

አማርኛ

-

Bahasa Melayu

-

தமிழ்

-

Filipino

-

Bahasa Indonesia

-

magyar

-

Română

-

Čeština

-

हिन्दी

-

فارسی

-

Kiswahili

-

Slovenčina

-

Slovenščina

-

Norsk

-

Svenska

-

українська

-

Ελληνικά

-

Suomi

-

עברית

-

Dansk

-

বাংলা

-

Hrvatski

-

Afrikaans

-

Gaeilge

-

Eesti keel

-

Māori

-

සිංහල

-

Azərbaycan dili

-

Euskara

-

Беларуская мова

-

Български

-

guarani

-

Kreyòl ayisyen

-

Kurdî

-

Lietuvių

-

Македонски

-

తెలుగు