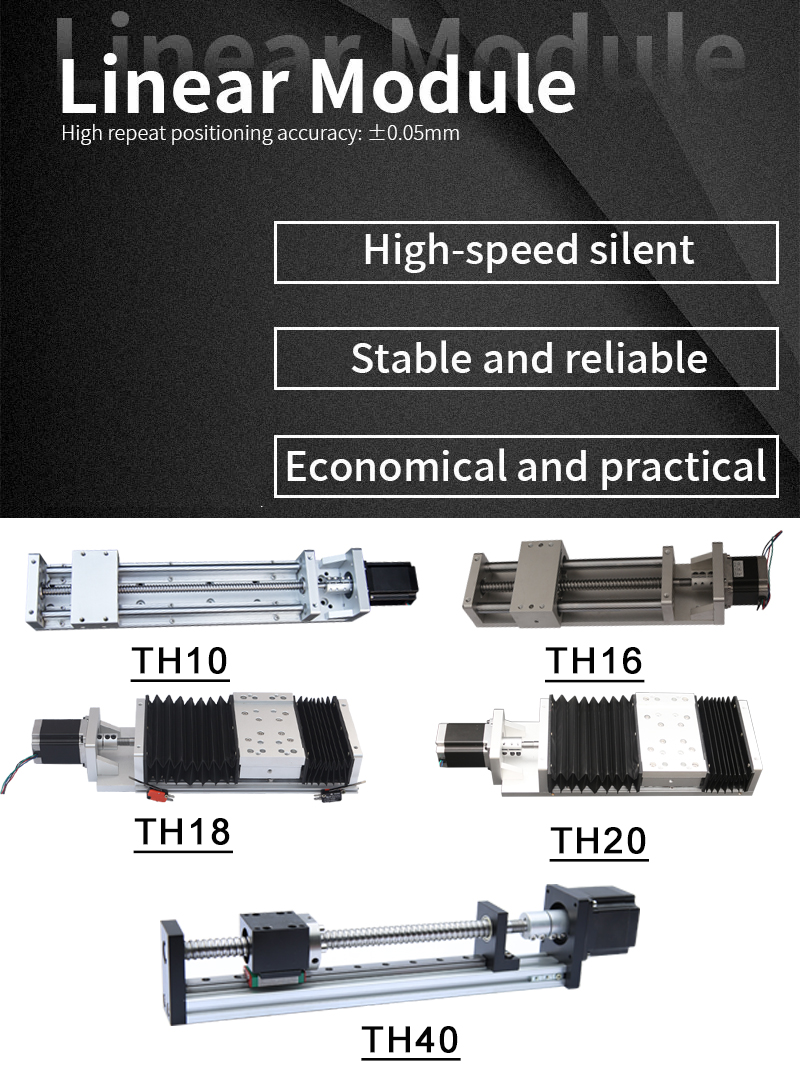

1.Application overview of precision linear guide slide module:

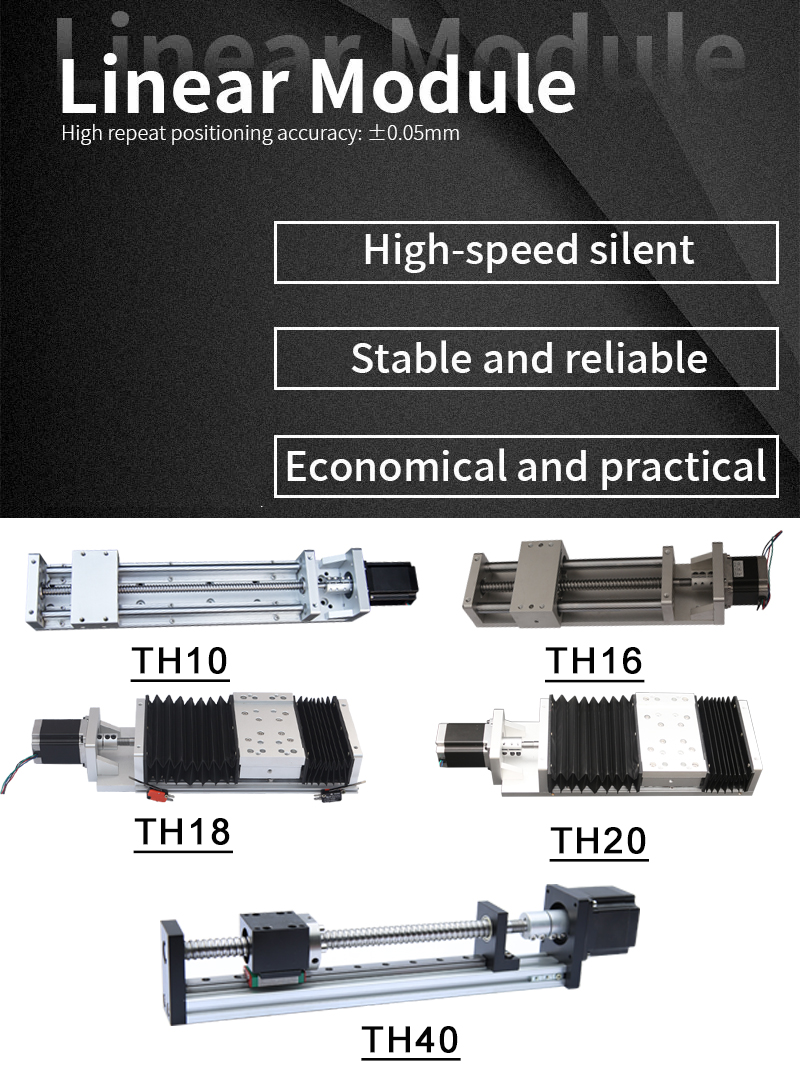

precision linear sliding table mold: With stable structure, high cost performance, high working accuracy, flexible application, strong adaptability, it is widely used in intelligent chemical factories, mechanical equipment, electric tools, electronic products.

2.Introduction of precision linear guide slide module:

(1)The sliding table of the precision linear slide module adopts SBR high load bearing guide rail (between the two guide rails) structure, which has high precision and good mechanical activity. The frame structure of the precision linear slide module slide table, such as the bottom plate, front and rear plates, moves The panel is made of 6061, 6063 aluminum alloy with light weight and high hardness, which has small thermal deformation and high feed stability, thus ensuring the actual accuracy of the processing state (under load) within the error accuracy of 0.05 to 0.03mm. So precision Linear sliding table module sliding table is an ideal component to achieve high precision and flexibility. It is widely used in numerical control and automation.

(2)The load on the sliding table of the precision linear slide module is generally 150-200kg, so the production efficiency is relatively high, and the load capacity is large. The best and ideal part of the precision linear slide module slide is used to Machining small workpieces. The characteristics of lightness and good positioning of work finishing are suitable for the horizontal plane, vertical plane, inclined plane, T-slot, various combined planes and boring processing occasions of small and medium-sized parts.

(3)The sliding table of the precision linear sliding table module is easy to maintain and easy to maintain. Regular maintenance can reduce wear, maintain accuracy and extend the life of the sliding table. The sliding table is equipped with a telescopic protective cover to keep the sliding table screw rod clean, and the screw rod is lubricated and protected. Conducive to normal use in environments with high dust, high humidity and high oil pollution.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు