In the realm of modern engineering and automation, the Lead Screw Stepper Motor stands as an invaluable innovation, powering a myriad of applications with its precision and efficiency. Whether you're a seasoned engineer or an enthusiast eager to delve into the world of motion control, understanding the mechanics, applications, and advantages of these motors is crucial. In this comprehensive guide, we, as experts in the field, are here to provide you with an in-depth exploration of Lead Screw Stepper Motors, ensuring that you not only grasp their significance but also gain the knowledge required to make informed decisions when integrating them into your projects.

What is a Lead Screw Stepper Motor?

At its core, a lead screw stepper motor is a specialized type of stepper motor that transforms electrical pulses into precise linear movements. Unlike conventional motors that rotate continuously, these motors convert electrical signals into incremental angular movements, ensuring precise and controlled motion.

How Does It Work?

The operation of a lead screw stepper motor is a symphony of precision engineering. It primarily consists of two key components:

The Stepper Motor: This is the heart of the system. It receives electrical pulses, also known as steps, which are sent through its coils. These pulses energize the coils in a specific sequence, causing the motor to move in discrete steps. Each step corresponds to a fixed angular displacement.

The Lead Screw: The stepper motor's output shaft is connected to a threaded rod known as the lead screw. As the motor steps, it turns the lead screw, resulting in linear motion. The pitch of the lead screw, which is the distance the screw moves with each complete rotation, determines the motor's linear resolution.

Precision at Its Best

One of the standout features of lead screw stepper motors is their exceptional precision. These motors can achieve impressively high accuracy levels, making them ideal for applications demanding meticulous control over movement. The precision is attributed to their ability to move in fixed increments, ensuring that the position is maintained with minimal deviation.

The Basics of a Lead Screw Stepper Motor

A Lead Screw Stepper Motor, at its core, is a subcategory of stepper motors. It's characterized by its unique mechanism, where rotary motion is converted into linear motion, making it particularly well-suited for tasks that demand precise and controlled linear movement. The magic happens when this motor is coupled with a threaded rod known as a "lead screw" or "acme screw." As the stepper motor rotates, it drives the lead screw to move forward or backward, depending on the rotation direction. This transformation of rotational energy into linear motion makes it incredibly versatile.

Key Components of a Lead Screw Stepper Motor

To better understand how a Lead Screw Stepper Motor operates, let's break down its key components:

Stepper Motor: The heart of the system, a stepper motor is an electromagnetic device that divides a full rotation into a series of equally spaced steps. This allows for precise control over the movement, making it ideal for applications requiring accuracy.

Lead Screw: The threaded rod, often made of materials like stainless steel or brass, serves as the intermediary between the motor's rotation and linear motion. It's designed with a pitch, which determines how far the nut moves with each rotation of the screw.

Nut: The nut, also known as a lead screw nut, is mounted on the lead screw. It is responsible for translating the rotational movement of the motor into linear motion.

Bearings: Bearings are crucial to reduce friction and ensure smooth motion. They are usually placed at the ends of the lead screw to support its movement.

Housing: This is the outer casing that encloses the motor and its components, protecting them from environmental factors and ensuring safe operation.

Applications of Lead Screw Stepper Motors

Lead Screw Stepper Motors find applications across various industries due to their precision and repeatability. Here are some of the key areas where these motors are indispensable:

1. CNC Machinery

In the world of Computer Numerical Control (CNC) machinery, precision is paramount. Lead Screw Stepper Motors are frequently used to control the movement of cutting tools, ensuring that intricate designs and shapes are carved with accuracy.

2. 3D Printing

The 3D printing revolution relies heavily on Lead Screw Stepper Motors. These motors drive the motion of the printer head and build platform with precision, layer by layer, creating intricate 3D models.

3. Medical Devices

In medical devices, where precise control is essential, Lead Screw Stepper Motors power devices like syringe pumps, robotic surgery equipment, and diagnostic machines, ensuring the highest level of accuracy in medical procedures.

4. Camera Sliders and Gimbals

For videographers and photographers seeking smooth and precise camera movement, Lead Screw Stepper Motors are employed in camera sliders and gimbals, enabling stunning cinematic shots and time-lapse videos.

5. Automated Manufacturing

Automated manufacturing systems use Lead Screw Stepper Motors to control the precise positioning of products along assembly lines, guaranteeing consistency and quality in the final output.

Advantages of Using Lead Screw Stepper Motors

The advantages of Lead Screw Stepper Motors are manifold, making them a preferred choice for applications demanding accuracy and control:

1. High Precision

The unique step-by-step movement of the motor allows for precise control, enabling accurate positioning and repeatability, even in the most demanding applications.

2. Compact Design

These motors are known for their space-saving design, making them ideal for situations where real estate is at a premium.

3. Cost-Effective

Lead Screw Stepper Motors are often a cost-effective choice compared to other precision motion control systems, making them accessible for a wide range of applications.

4. Low Maintenance

With fewer mechanical parts, these motors require minimal maintenance, reducing downtime and operational costs.

5. Energy-Efficient

Lead Screw Stepper Motors consume power only during movement, contributing to energy efficiency in various applications.

Selecting the Right Lead Screw Stepper Motor

Choosing the ideal Lead Screw Stepper Motor for your project necessitates a thorough understanding of your requirements. Consider the following factors when making your selection:

1. Load Capacity

Determine the maximum load the motor will need to move, as this will influence the size and power of the motor required.

2. Speed and Precision

Evaluate the speed and precision required for your application. Some applications may demand slower, more precise movements, while others require quick, accurate positioning.

3. Environmental Factors

Consider the environmental conditions in which the motor will operate. Factors like temperature, humidity, and exposure to contaminants can influence your choice.

4. Budget

Ensure that the motor you choose aligns with your budget constraints. While Lead Screw Stepper Motors are cost-effective, there are variations available to suit different price points.

In conclusion, Lead Screw Stepper Motors are indispensable in various industries, facilitating precise and controlled linear motion. Their unique mechanism, coupled with the advantages they offer, positions them as a superior choice for applications that require accuracy and efficiency. Selecting the right motor for your project is essential, and by considering factors such as load capacity, speed, precision, environmental conditions, and budget, you can ensure that you harness the full potential of these remarkable motors.

Related searches:

Lead screw stepper motorarduino

Lead screw stepper motor forsale

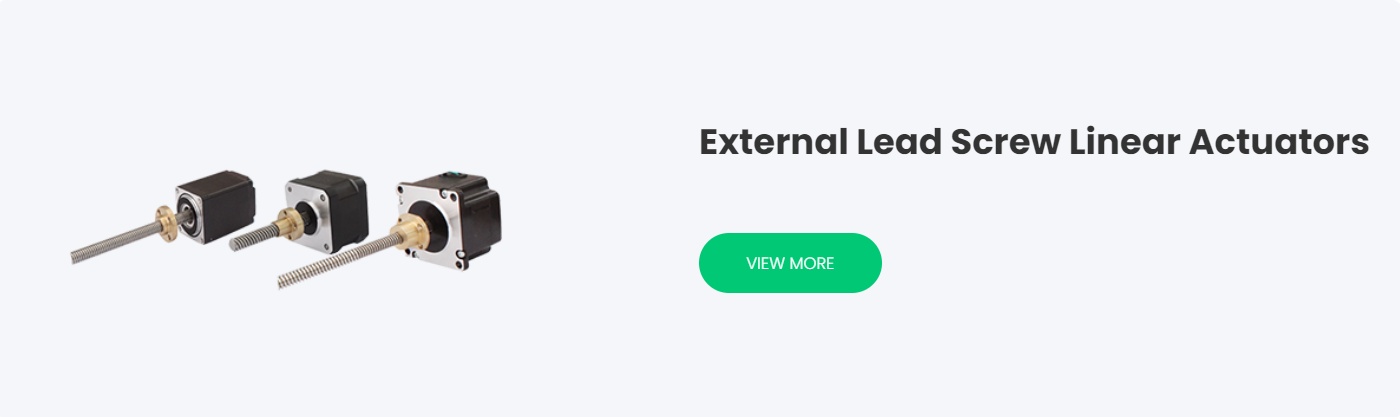

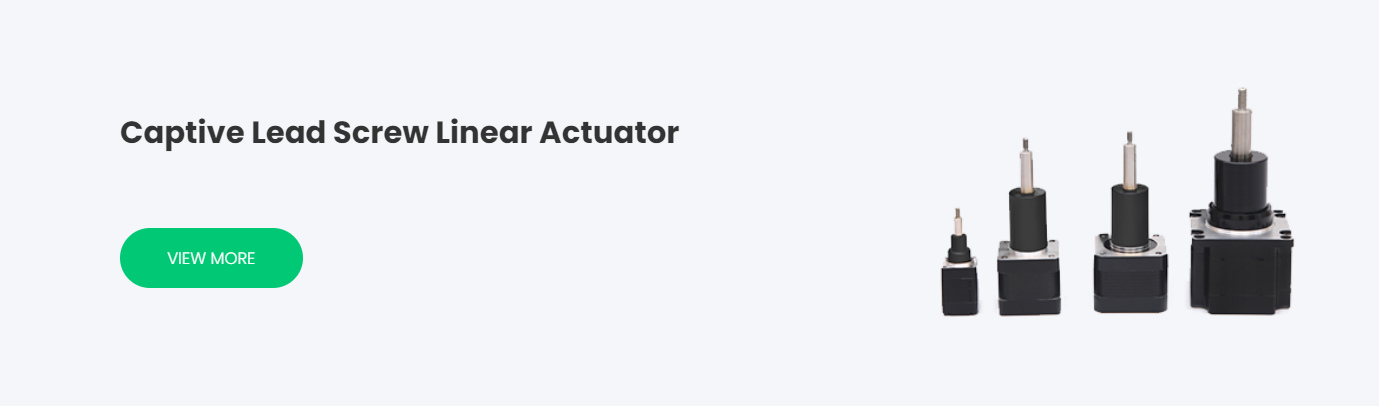

Lead screw actuator

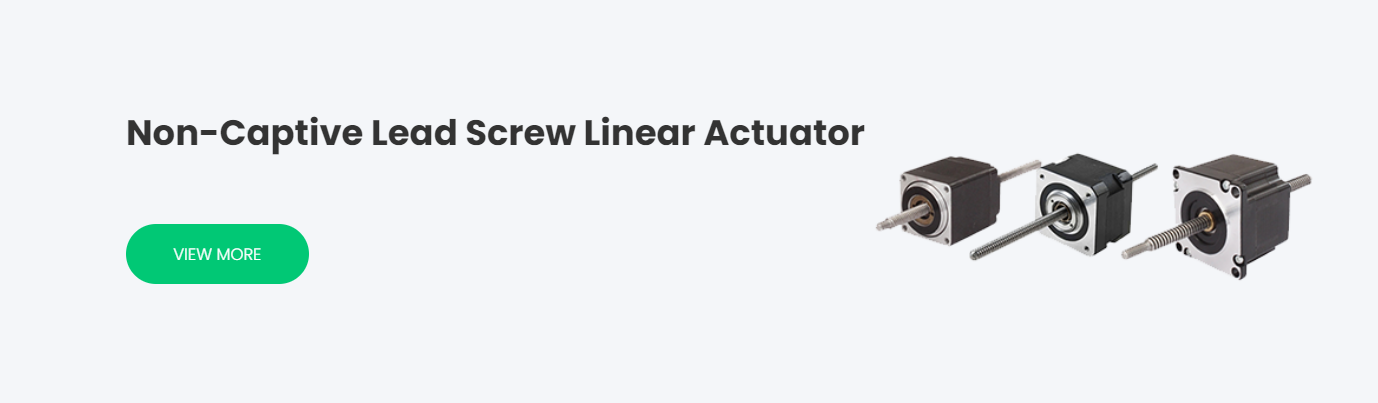

Non captive lead screwstepper motor

Lead screw stepper motor linearactuators

How to attach lead screw tostepper motor

Miniature stepper motor withlead screw

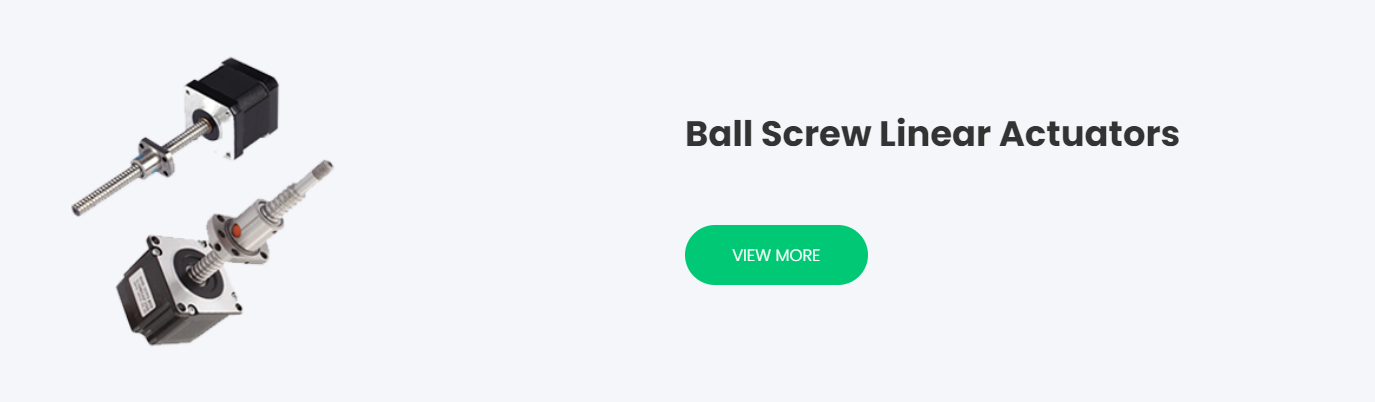

Ball screw actuator with motor

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు