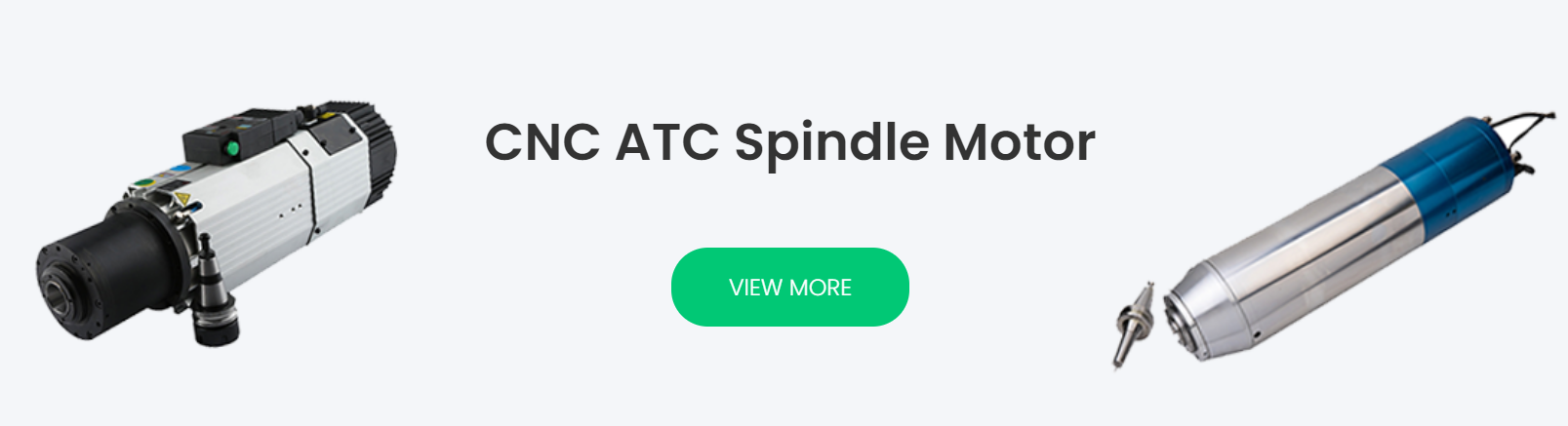

ATC (Automatic Tool Change) spindle motors are specialized electric motors designed for use in CNC (Computer Numerical Control) machines, which are used in precision manufacturing and machining applications. These motors are used to drive the cutting tools used in the machine, and they are capable of changing tools automatically during operation.

The ATC spindle motor is designed to provide high-speed rotation and precise control, making it ideal for applications where accuracy and repeatability are critical. These motors typically have a power rating of several kilowatts and can operate at speeds of up to tens of thousands of revolutions per minute.

One of the key features of an ATC spindle motor is its ability to change tools automatically, which allows the machine to perform complex machining operations without interruption. This is accomplished through the use of a tool changer that can quickly and accurately swap out cutting tools as needed.

ATC spindle motors are commonly used in a variety of industries, including aerospace, automotive, medical, and electronics manufacturing. They are often used in CNC milling machines, lathes, and other precision machining equipment. The specific characteristics of an ATC spindle motor will depend on the manufacturer and the intended application, but they generally offer high performance, precision, and reliability.

Advantage of atc spindle motor

The main advantages of ATC (Automatic Tool Change) spindle motors are:

1. Increased productivity

With an ATC spindle motor, the machine can automatically switch between different cutting tools without requiring manual intervention. This results in a significant increase in productivity and a reduction in downtime, as the machine can continue to operate without interruption.

2. Improved accuracy

ATC spindle motors are designed to provide precise control over the cutting tool, resulting in improved accuracy and repeatability. The ability to change tools automatically also reduces the risk of errors that can occur when changing tools manually.

3. Versatility

ATC spindle motors can accommodate a wide range of cutting tools, allowing for greater versatility in the types of operations that can be performed. This makes them ideal for applications that require a variety of cutting tools and machining processes.

4. Reduced operator fatigue

Since the ATC spindle motor automates the tool-changing process, the operator can focus on other tasks, reducing the risk of fatigue and improving safety.

5. Time-saving

The automatic tool change function saves time by eliminating the need for the operator to manually change the tool. This results in faster machining times and increased throughput.

Introduction of Spindle Motor Application

An ATC spindle motor is a type of high-speed spindle motor that is designed for use in CNC machines with automatic tool changers (ATC).

An ATC spindle motor is capable of quickly and automatically changing cutting tools during a machining operation, allowing for increased efficiency and productivity.

In a CNC machine with an ATC, the spindle motor is responsible for rotating the cutting tool to remove material from a workpiece. When a tool change is required, the ATC system will automatically remove the current tool from the spindle and replace it with a new tool from a magazine or carousel. This process is typically performed in a matter of seconds, allowing the machine to continue the machining operation without interruption.

Overall, the use of an ATC spindle motor can significantly improve the efficiency, accuracy, and versatility of a CNC machine, making it a valuable tool for precision manufacturing and machining applications.

Classification of atc spindle motor

ATC (Automatic Tool Change) spindle motors can be classified based on several factors, including their power rating, speed, and design. Here are some common classifications:

1. Power rating

ATC spindle motors are available in a range of power ratings, from a few kilowatts to several hundred kilowatts or more. The power rating of the motor will depend on the specific application requirements.

2. Speed

ATC spindle motors are designed to operate at high speeds, with typical speeds ranging from a few thousand to tens of thousands of revolutions per minute (RPM). The speed of the motor will depend on the specific application requirements.

3. Design

ATC spindle motors can be designed with different configurations, such as belt-driven, direct drive, or air-cooled. The design of the motor will depend on the specific application requirements and the type of machine in which it will be used.

4. Type of tool holder

ATC spindle motors can be classified based on the type of tool holder they use. Some motors use a standard tool holder, while others use a specialized tool holder that is specific to the machine or the application.

5. Type of application

ATC spindle motors can be classified based on the type of application for which they are designed. For example, some motors are designed for use in milling machines, while others are designed for use in lathes or other types of machines.

The specific classification of an ATC spindle motor will depend on the manufacturer, the intended application, and the specific requirements of the machine in which it will be used.

Types of Spindle Motors

There are two main types of spindle motors: AC and DC. AC spindle motors are more common and are used in most CNC machines. DC spindle motors, on the other hand, are used in specialized CNC machines that require high torque at low speeds. Of course, we can also be divided into the following categories:water cooled spindle motor, air cooled spindle motor, CNC ATC spindle motor and VFD CNC spindle motor.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు