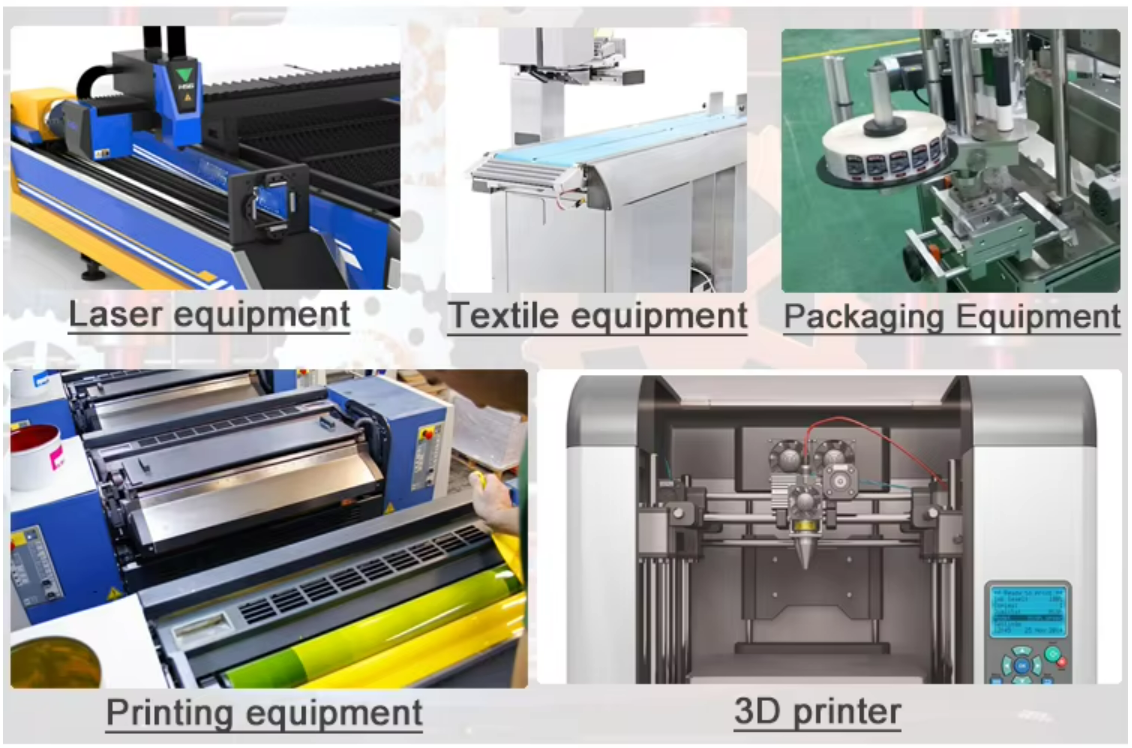

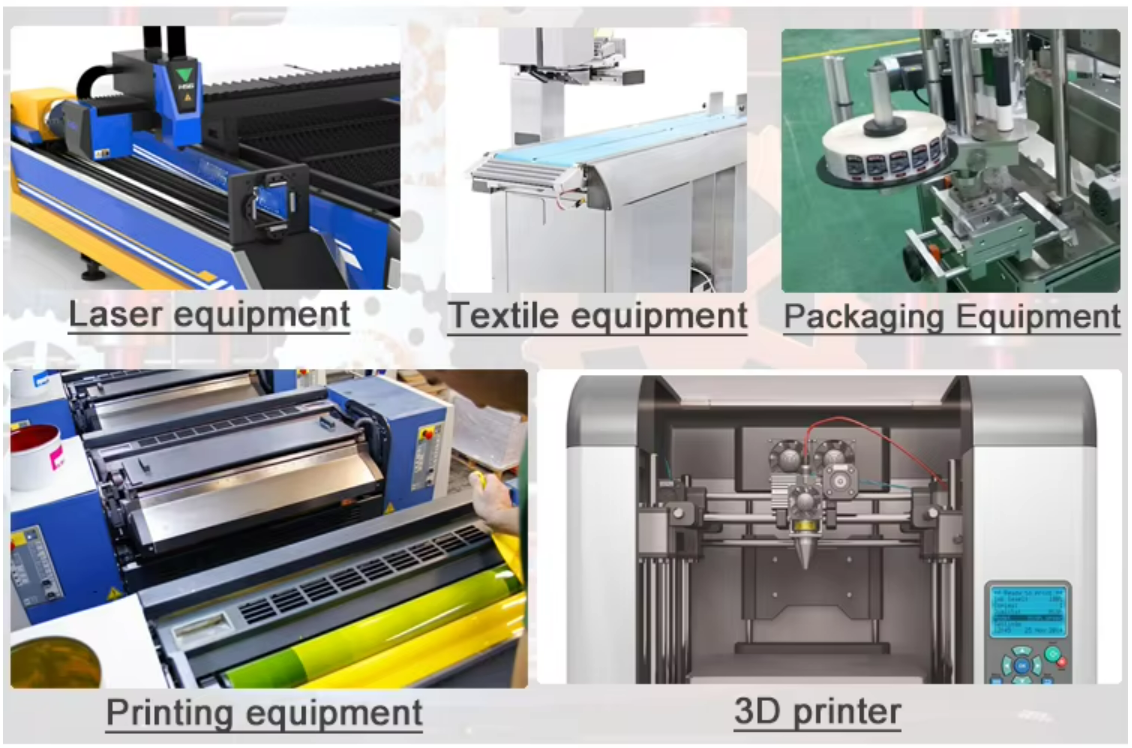

Stepper motors are popular for their ability to stop accurately as well as their ease of use. Both the amount of rotation and the speed are controlled easily with the same digital square wave pulse signal. Unlike servo motors, stepper motors do not need an encoder to operate. Example applications of stepper motors are CNC machines, index tables, robotics, scanners, and more recently, 3D printers.

Choosing the right stepper motor for your application involves understanding various factors, including the type of stepper motor, the application's requirements, and the environmental conditions. Here’s a guide to help you make an informed decision:

1. Types of Stepper Motors

Permanent Magnet (PM) Stepper Motor:

Characteristics:

Utilizes a permanent magnet rotor and is generally low-cost.

Best For:

Applications requiring low torque and speed, such as basic positioning tasks.

Variable Reluctance (VR) Stepper Motor:

Characteristics:

Features a soft iron rotor, which offers higher step resolution but lower torque compared to PM stepper motors.

Best For:

High-speed and low-torque applications where finer resolution is needed.

Hybrid Stepper Motor:

Characteristics:

Combines features of both PM and VR motors, offering high torque and precision with a permanent magnet and a toothed rotor.

Best For:

High-performance applications requiring precise control, such as 3D printers, CNC machines, and industrial automation.

2.Determine Application Requirements

Torque Requirements:

Assess the load that the motor will drive. The required torque depends on the weight, friction, and acceleration of the load.

Holding Torque:

The torque needed to maintain a position when the motor is stationary. This is crucial for applications like robotics or vertical movement systems.

Running Torque:

The torque needed during motion. This is vital for applications that involve continuous or dynamic movement.

Speed Requirements:

Stepper motors operate best at lower speeds. Consider the speed range required for your application and ensure the motor can handle it without losing steps.

Step Resolution:

Determine the precision required. Higher step counts (e.g., 200 steps per revolution) provide finer control but may require more complex drivers.

Microstepping:

Some applications benefit from microstepping, which increases resolution by dividing each full step into smaller increments.

Voltage and Current:

Match the motor’s voltage and current ratings with your driver and power supply. Higher voltage often means better performance at higher speeds, while higher current allows for greater torque.

Driver Compatibility:

Ensure that the motor is compatible with the driver you intend to use. Some drivers are specifically designed for certain types of stepper motors (e.g., bipolar or unipolar configurations).

3. Environmental Considerations

Temperature:

Stepper motors generate heat during operation. Consider whether the motor can withstand the environmental temperature, especially if it will be used in a confined space or near heat-sensitive components.

Vibration and Noise:

Some applications require quiet operation, so the noise level and vibration of the motor should be considered. Hybrid motors are typically quieter than PM or VR motors.

Humidity and Dust:

In harsh environments, choose motors with appropriate protective features (e.g., IP ratings) to prevent damage from moisture or dust.

4. Physical Size and Mounting

Motor Size:

Ensure the motor fits within the physical constraints of your application. The size of the motor often correlates with its torque output.

Mounting Configuration:

Consider how the motor will be mounted. Standard NEMA frame sizes (e.g., NEMA 17, NEMA 23) are common, but make sure the motor’s mounting holes align with your system’s design.

5. Cost vs. Performance

Balance the motor’s cost with its performance characteristics. While hybrid stepper motors offer better precision and torque, they are more expensive than PM or VR motors. Choose a motor that meets your application’s requirements without over-engineering.

6. Testing and Prototyping

Before finalizing your choice, test the motor in your specific application. Prototyping can help you identify any issues with torque, speed, or compatibility before mass production.

Choosing the right stepper motor involves careful consideration of the motor type, application requirements, environmental conditions, and cost. By thoroughly evaluating these factors, you can select a motor that will provide reliable and efficient performance for your specific application.

86x86x118mm NEMA 34 Hybrid Stepping motor For CNC

Holry 34mm length Nema8 20mm 1.8Ncm 0.2A stepper motor with driver for 3D printer

NEMA 17 Stepping motor with ce For 3D Printer

When does it make sense to use a specific type of stepper motor? It depends on your application.

Performing quick indexing operations over short distances

Achieving high-speed reciprocating motion

Performing indexing operations of a large inertial load

Performing indexing operations with a higher stop accuracy

Performing vertical positioning operation with power-off braking

Performing closed-loop positioning operation

Positioning within a small space

The Advantages of Stepper Motors

Stepper motors offer several advantages that make them ideal for a wide range of applications, particularly those requiring precise control of position, speed, and acceleration. Here are the key advantages of using stepper motors:

1. Precise Positioning and Repeatability

Accuracy:

Stepper motors move in fixed, discrete steps, allowing for precise control over the position. Each step corresponds to a specific angle of rotation, ensuring consistent and repeatable movements.

No Feedback Required:

Unlike servo motors, stepper motors do not require a feedback system (like an encoder) to maintain position, simplifying design and reducing cost.

2. Simple Control Systems

Open-Loop Control:

Stepper motors can be controlled using open-loop systems, where the controller sends step pulses without needing to monitor the motor’s position. This simplicity reduces system complexity and cost.

Ease of Integration:

Stepper motors are easy to interface with microcontrollers and other digital control systems, making them suitable for applications in robotics, automation, and more.

3. High Torque at Low Speeds

Direct Drive Capability:

Stepper motors provide high torque at low speeds, making them ideal for direct drive applications without the need for complex gearing.

Holding Torque:

Stepper motors can maintain a holding torque when stationary, which is useful in applications where maintaining a fixed position is critical, such as in CNC machines and 3D printers.

4. Excellent Stability

No Drift:

Once in position, stepper motors do not drift, ensuring stable operation. This stability is particularly beneficial in applications requiring long periods of holding position without movement.

5. Reliability and Durability

Long Lifespan:

Stepper motors have fewer moving parts than other types of motors, leading to higher reliability and a longer operational lifespan.

Low Maintenance:

The robust design and lack of brushes or commutators mean that stepper motors require minimal maintenance compared to brushed motors.

6. Wide Range of Sizes and Configurations

Versatility:

Stepper motors are available in various sizes, step resolutions, and torque ratings, allowing for customization to suit specific application needs.

Adaptability:

They can be configured for different operation modes, including full-step, half-step, and microstepping, offering flexibility in performance characteristics.

7. Cost-Effective Solution

Affordable:

Stepper motors are generally more cost-effective than other precision motors like servos, especially in applications where the motor's inherent advantages eliminate the need for additional components like encoders.

Lower System Costs:

The simplicity of the control system and the absence of feedback components reduce the overall cost of the system.

8. High Reliability in Low-Speed, High-Torque Applications

No Resonance Issues at Low Speeds:

Stepper motors are particularly effective in low-speed, high-torque applications where other motors might experience issues with resonance or require complex control algorithms.

9. No Tuning Required

Ease of Use:

Unlike servo motors, stepper motors do not require tuning of control loops, which simplifies setup and reduces the time required for deployment.

10. Compatibility with Modern Controllers

Integration with Microstepping Controllers:

Modern stepper motor drivers can use microstepping to increase the resolution and smoothness of motion, making stepper motors even more versatile and precise.

Stepper motors are a popular choice for applications requiring precise control, reliability, and simplicity. Their ability to provide accurate positioning, high torque at low speeds, and compatibility with simple control systems makes them ideal for a wide range of applications, from robotics to industrial automation. Additionally, their cost-effectiveness and durability make them a practical choice for both small-scale projects and large industrial systems.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు