Foreword:What does an NEMA stand for?

NEMA is The National Electrical Manufacturers Association (NEMA) is an organization that forms the standards for the manufacturing of medical imaging equipment and electrical equipment. The purpose is to provide the safety, environment, and marketing enhancement of the industry.

You will also be curious about the name of the motor, why there is the name NEMA, then let me answer this question for you.

NEMA stands for National Electrical Manufacturers Association, which was founded in 1926 to set standards for companies that manufacture electrical products. NEMA enclosure ratings apply to virtually any type of electrical equipment or wiring installed outdoors or in industrial facilities. Originally, NEMA's goal was to ensure the quality of electrical equipment, components, and wiring. However, as technology continues to develop, so does the security of protecting it. Today, electrical components like controllers, vulnerable devices, and wiring need to be protected from the applications and environments in which they are used. The way to provide this protection is to house them in an enclosure or cabinet.

Introduction of nema 17 stepper motor

Nema stepper motor is a commonly used stepper motor, which refers to a type of motor whose external dimensions are 42mm x 42mm. It has high positioning accuracy, excellent control performance and stable and reliable operation characteristics, so it is widely used in motion control systems of various mechanical equipment.

The characteristic of the nema 17 stepper motor is that it has 4 phases, the phase difference of each phase is 90 degrees, and one step is the excitation of one phase. Each stepper motor can produce precise stepping motion, which makes it very suitable for Applications that require precise control of motion. In the control of mechanical equipment, nema 17 stepper motors can precisely control the speed and direction of motion of the motor by controlling the current.

Video of nema 17 stepper motor

Parameter introduction of nema 17 stepper motor

1. Step angle

Nema 17 stepper motors usually include two step angles of 1.8 degrees and 0.9 degrees. The motor with a step angle of 1.8 degrees needs 200 step signals per revolution, while the motor with a step angle of 0.9 degrees needs 200 step signals per revolution. 400 step signals are required.

2. Rated voltage and current

The rated voltage and current of a Nema 17 stepper motor are usually determined by its working environment and load requirements. Generally, its rated voltage is 12V, 24V or 48V, and its rated current ranges from 1A to 5A.

3. Rated torque

The rated torque of the 42 stepper motor is also determined by its working environment and load requirements. Generally, the specific parameters of its rated torque can be found in our product link, or consult us for more detailed product data.

4. Drive method

42 Stepper motors usually adopt a two-phase or four-phase drive mode, in which the motor with the two-phase drive mode only needs two signal lines for control, while the motor with the four-phase drive mode requires four signal lines for control.

5. Temperature range

The operating temperature range of 42 stepper motors is usually -20°C~+50°C, but there are also some high-temperature or low-temperature models, which need to be selected according to the specific use environment. Of course, if your system has a cooling system, you can say otherwise. The specific situation is yours You can also contact us, we also provide product customization services.

Summary

NEMA 17 stepper motors are a type of electric motor that are widely used in various motion control applications, such as 3D printers, CNC machines, robotics, and automation systems. They are designed to provide high precision and accuracy, as well as maintain torque at low speeds, making them an ideal choice for applications that require precise and repeatable movements.

nema 17 stepper motor specifications

Stepper motor, high torque, low noise, smooth type, step angle: 1.8° or 0.9°, NEMA17, 42x42mm

Optional: Lead-wires, gearbox, encoder, brake, integrated drivers...

| MODEL | Rated Current

(A) | Phase Resistance

(Ω) | Phase Inductance

(mH) | Lead Wire

(No.) | Holding Torque

(N.cm) | Motor Length

L(mm) | Rotor Inertia

(g.cm²) | Motor Weight

(g) |

| 42HB34F04AB | 0.4 | 33 | 45 | 4 | 24 | 34 | 34 | 200 |

| 42HB34F08AB | 0.8 | 6.2 | 10 |

| 42HB34F105B | 1.5 | 1.8 | 2.4 |

| 42HB40F04AB | 0.5 | 8 | 15 | 4 | 35 | 40 | 50 | 220 |

| 42HB40F102B | 1.2 | 6 | 13 |

| 42HB40F107B | 1.7 | 1.5 | 2.5 |

| 42HB48F04AB | 0.4 | 20 | 40 | 4 | 45 | 48 | 68 | 280 |

| 42HB48F08AB | 0.8 | 9 | 15 |

| 42HB48F105B | 1.5 | 2.8 | 4.8 |

| 42HB34MF06AB | 0.6 | 4.2 | 4 | 4 | 16 | 34 | 34 | 200 |

| 42HB34MF04AB | 0.4 | 10 | 9.5 |

| 42HB40MF102AB | 1.2 | 3.3 | 4 | 4 | 26 | 40 | 54 | 220 |

| 42HB40MF107AB | 1.7 | 1.65 | 4 |

| 42HB48MF102AB | 1.2 | 3.3 | 4 | 4 | 35 | 48 | 68 | 350 |

| 42HB48MF107AB | 1.68 | 1.65 | 4.1 |

Application OF Nema 17 Stepper Motor

Stepper motor a type of DC motors that move in increments or steps, they move at a known interval for each pulse of power. These pulses of power are provided by a motor driver and is referred to as a step. As each step moves a known distance it makes them handy devices for repeatable positioning. Stepper motors are used in the following fields:

1. PCBA

Mounter: Mounter is a device used for automatic welding of components in PCBA assembly, because the machine needs to control the precise position and speed of components, which is conducive to precise welding work. Because the stepper motor has the characteristics of high precision and high torque, the application of the stepper motor is adopted in this aspect, which makes the placement machine run at high speed and weld accurately.

2. DISPENSER

Cargo lane motor: The cargo lane motor is a motor used in vending machines to push goods out of the goods lane. It is necessary to precisely control the position and speed of the goods lane motor in order to push the goods to the corresponding outlet. The high precision and reliability of the stepper motor can ensure the precise positioning and high-speed operation of the cargo lane motor.

Pick-up motor: The pick-up motor is a motor used in vending machines to push goods out of the outlet. It is necessary to precisely control the position and speed of the pick-up motor in order to push the goods into the hands of buyers. The high-precision and high-torque characteristics of the stepper motor can ensure the high-speed operation of the picking motor and the precise release of products.

Coin acceptor motor: The coin acceptor motor is a motor used to receive coins in a vending machine. It is necessary to precisely control the position and speed of the coin acceptor motor in order to push the coins into the corresponding memory. The high precision and high reliability of the stepper motor can ensure the coin acceptor motor to receive and store coins accurately.

PCBA

DISPENSER

PHONE PRODUCTION LINE

ROBOT ARMS

Detailed Introduction OF Nema 17 Stepper Motor

NEMA 17 stepper motors(Nema 17 - 42 x 42mm Stepper Motor) are those that have a 1.8 degree step angle. NEMA 17 steppers typically have more torque than smaller variants, such as NEMA 14 and have a recommended driving voltage of 12-24V. What's more, NEMA 17 stepper motors are compliant with relevant US laws and regulations, ensuring that they meet the highest standards of safety and reliability.

Summarize

Our NEMA 17 stepper motors are available in bipolar and unipolar configurations, allowing you to choose the motor that best fits your specific needs. They have a step angle of 1.8 degrees , offering a wide range of speeds and torques for your motion control applications.Choose NEMA 17 stepper motors for your motion control applications and experience the reliability, versatility, and ease of use that only NEMA-compliant motors can offer!

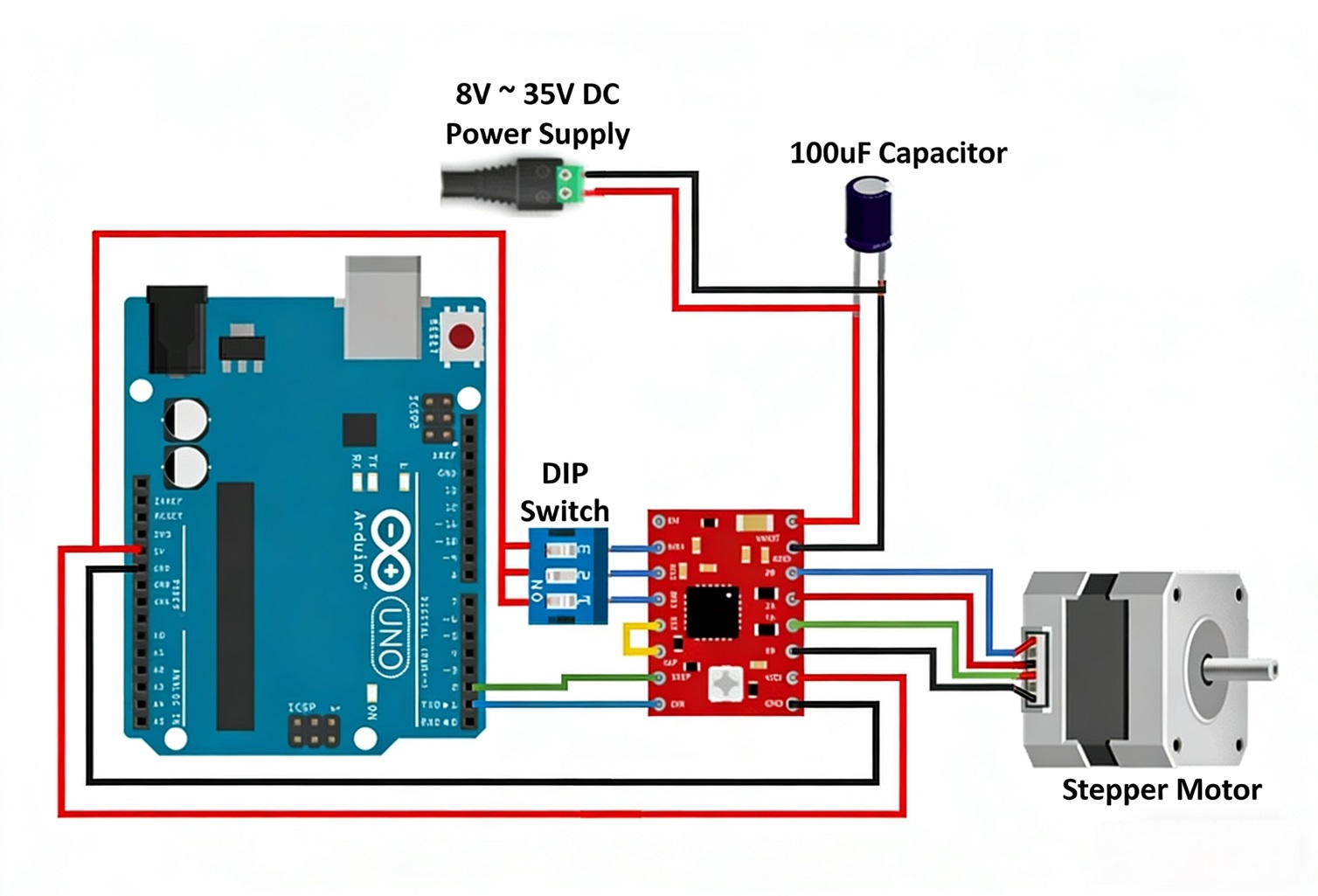

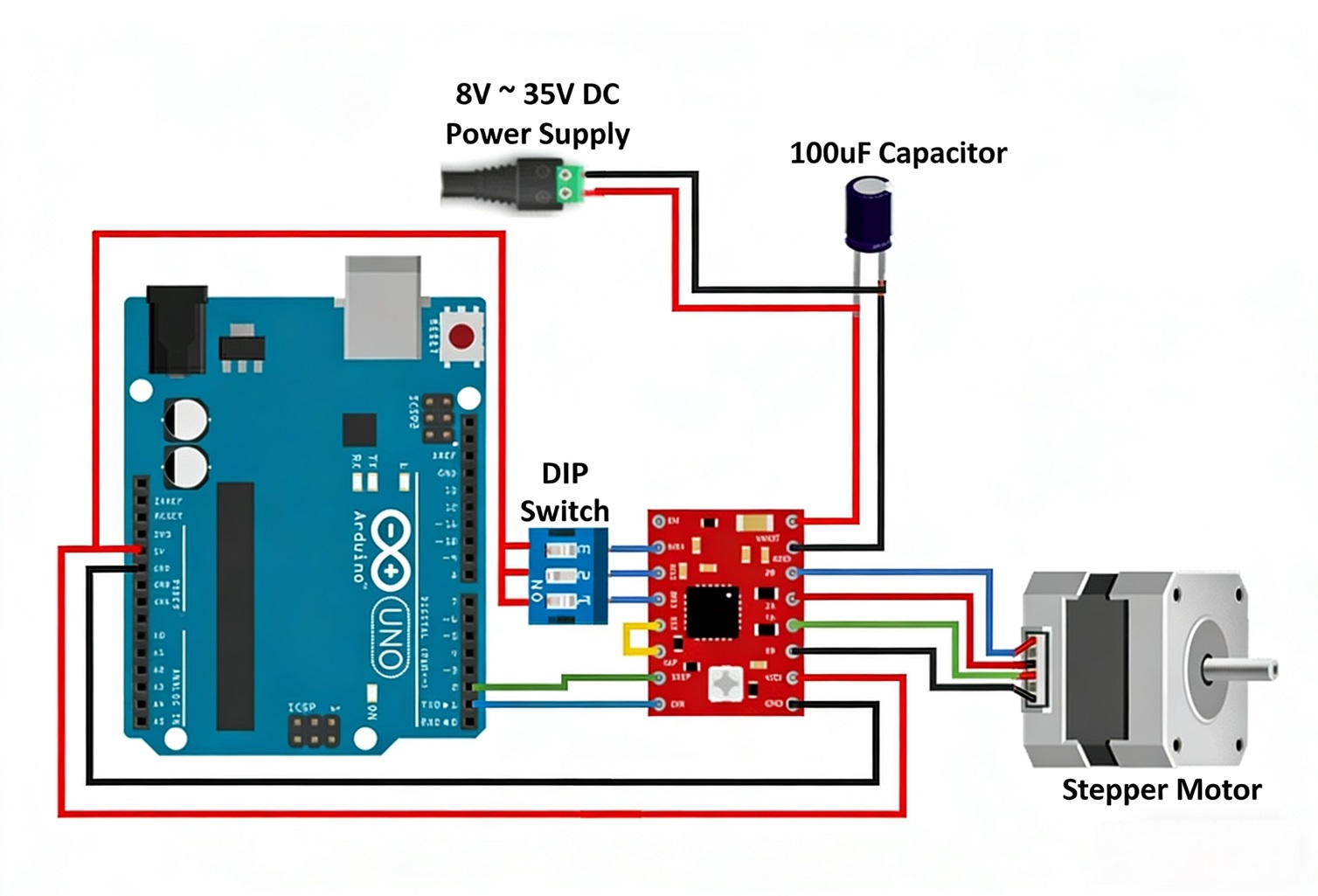

driver for nema 17 stepper motor

NEMA 17 stepper motors are popular in 3D printers, CNC machines, robotics, and automation projects due to their compact size (42x42mm faceplate), precise control, and holding torque typically ranging from 0.3 to 0.6 Nm. These bipolar motors usually feature a 1.8° step angle (200 steps per revolution) and require a dedicated driver to operate efficiently, as direct control from microcontrollers like Arduino can damage components.

A stepper motor driver manages current flow to the motor coils, enabling microstepping for smoother motion, reduced vibration, and higher resolution. Common drivers include the A4988, a compact, affordable option supporting up to 2A (with heatsink) and 1/16 microstepping—ideal for hobbyists using Arduino or Raspberry Pi.

For higher performance, the DRV8825 offers similar features with better current handling, while advanced options like TMC2209 provide silent operation via stealthChop technology. Industrial choices such as TB6600 (up to 4A) or DM542T deliver robust torque and low noise for demanding applications.

stepper motor drivers

stepper motor & drivers

Selecting a driver depends on current rating (match motor's 1-2A typical), voltage (12-24V supply), and features like overcurrent protection. Proper heatsinking and current limiting are essential to prevent overheating. With the right driver, NEMA 17 motors achieve reliable, precise positioning in diverse projects.

Nema 17 Stepper Motor FAQ:

What is a NEMA 17 stepper motor?

NEMA 17 stepper motor is a type of bipolar or unipolar stepper motor with a 1.7 x 1.7-inch (43.2 x 43.2 mm) faceplate size. The term “NEMA 17” refers to the mounting standard, not its electrical or mechanical performance. These motors are commonly used in 3D printers, CNC machines, and robotics for precise position control.

How does a NEMA 17 stepper motor work?

NEMA 17 motor operates by energizing its coils in a sequence, causing the rotor to move in discrete steps. Each pulse sent to the motor driver rotates the motor shaft by a fixed angle (commonly 1.8° per step, or 200 steps per revolution). This step-by-step motion allows for accurate positioning without feedback sensors.

What are the key specifications to look for in a NEMA 17 motor?

Important parameters include:

Step angle (e.g., 1.8° or 0.9°)

Holding torque (measured in N·cm or oz·in)

Rated current per phase

Voltage

Resistance and inductance per winding

Shaft type and length

These specs determine torque output, speed, and compatibility with your driver or controller.

What driver should I use with a NEMA 17 stepper motor?

Common stepper drivers include the A4988, DRV8825, TMC2208, or TMC2209, depending on your current requirements and noise tolerance.

A4988 → Basic, affordable, suitable for low-current applications.

DRV8825 → Handles higher current and microstepping options.

TMC2209 → Very quiet, efficient, and supports sensorless homing (great for 3D printers).

How do I power a NEMA 17 stepper motor?

NEMA 17 motors are typically powered by 12V to 24V DC, depending on your driver’s capability. The driver regulates current to the motor windings, so set the current limit correctly to prevent overheating. Always connect the motor to the driver before powering on to avoid damage.

Why is my NEMA 17 motor skipping steps or vibrating?

Skipping or vibration can be caused by:

Insufficient current or incorrect driver settings

Mechanical binding or excessive load on the shaft

Low supply voltage

Microstepping mismatch between driver and controller

To fix this, increase the current limit slightly, check mechanical alignment, and ensure proper microstepping configuration in your firmware or driver.

What is the difference between a bipolar and unipolar NEMA 17 stepper motor?

Bipolar stepper motor has four wires and requires current to flow in both directions through each coil. It provides higher torque and is more common in modern applications.

A unipolar stepper motor typically has five or six wires and is easier to drive but delivers less torque for the same size. Most 3D printers and CNC machines use bipolar NEMA 17 motors for better performance.

Can I use NEMA 17 stepper motors for continuous rotation applications?

Yes, but with limitations. Stepper motors are designed for precise positioning, not high-speed continuous rotation. If you need smooth, fast, or energy-efficient rotation, a DC or brushless motor is usually better. However, for slow, controlled, or intermittent movement, NEMA 17 motors perform very well.

How do I determine the torque required for my application?

To size your NEMA 17 motor correctly, calculate the load torque your system needs to move or hold. Consider factors such as:

Weight of the moving parts

Friction in the mechanical system

Speed requirements (higher speed = less torque)

Gear ratio or lead screw pitch (if applicable)

Once you know the required torque, choose a NEMA 17 motor that provides at least 25–30% higher holding torque than your calculated value for reliable operation.

HOLRY is your expert stepper motor supplier. We are always online

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు