Brief Description

1. Small step angle and high precision;

2. The number of pole pairs is equal to the number of rotor teeth, which can be changed in a wide range according to needs;

3. The winding inductance changes little with the rotor position, which is easy to achieve the best operation control;

4. Axial magnetizing magnetic circuit, using a new type of permanent magnet material with high magnetic energy product, is conducive to the improvement of motor performance;

5. The rotor magnet provides excitation; there is no obvious oscillation in the entire operating area.

Naming Rules

42 HB 40 F 105 B- -06 ○1 ○2 ○3 ○4 ○5 ○6 ○7

○1: 42: Motor frame: 42*42mm

○2: HB: Hybrid stepping motor

○3: 40: Length of motor body

○4: F: Number of leads: four lines, S: six lines, E: 8 lines

○5: 105: Motor rated current value 1.5A

○6: B: There is a flat wire on the motor shaft, CL stands for gear D stands for double output shaft PJ stands for keyway

○7: 06: Derivative number

Brief Introduction of Technical Characteristics

General technical characteristics

● The stepping motor is used in low-speed occasions---the speed does not exceed 1000 revolutions per minute, (6666PPS at 0.9 degrees), preferably between 1000-3000PPS (0.9 degrees), and it can be used here by a decelerating device. When the motor has high working efficiency and low noise;

● It is best not to use the full-step state for the stepping motor, because the vibration is large in the full-step state;

● The voltage value in the motor specification is not the driving voltage volt value. The specific driving voltage can be selected according to the stepper driver (recommendation: 42 and below motors use 12-24V, 57 motors use DC 24V-48V, 86 use DC 48-80V, 110 The motor adopts higher than DC 80V)

● For loads with large moments of inertia, a large frame size motor should be selected;

● When the motor is in a relatively high-speed or large inertia load, it generally does not start at the working speed, but uses a gradual frequency increase to increase the speed. First, the motor does not lose step, and second, it can reduce the noise and improve the positioning accuracy of the stop;

● For high precision, it should be solved by mechanically decelerating, increasing the motor speed, or using a driver with a high subdivision number;

● The motor should not work in the vibration zone, if necessary, it can be solved by changing the voltage, current or adding some damping;

● When the motor works below 600PPS (0.9 degrees), it should be driven by small current, large inductance, and low voltage.

Mechanical technical characteristics

● When installing/removing the shaft end of a stepping motor with a coupling part, do not directly hit the shaft end with a hammer. (The hammer hits the shaft end directly, and the encoder at the other end of the stepper motor shaft may be damaged);

● Try to align the shaft ends to the best condition to ensure good concentricity, otherwise vibration may occur, the bearing may be damaged, and the shaft may even be broken;

● The motor can be used in places that will be attacked by water or oil drops, but it is not completely waterproof or oil-proof. The default protection level is IP54. Therefore, the motor should not be placed or used in an environment corroded by water or oil (if necessary For special protection level, please contact us!);

● If the motor is connected to a reduction gear, oil seals should be added when using a stepper motor to prevent the reduction gear from entering the stepper motor;

● Do not immerse the motor cable in oil or water. Ensure that the cable is not subjected to moment or vertical load due to external bending force or its own weight, especially at the cable outlet or connection.

● When the motor is moving, the cable (that is, the one configured with the motor) should be firmly fixed to a stationary part (relative to the motor) and an additional cable loaded in the cable support should be used to delay it, so that the bending stress Can be reduced to the minimum. The radius of the cable elbow should be as large as possible

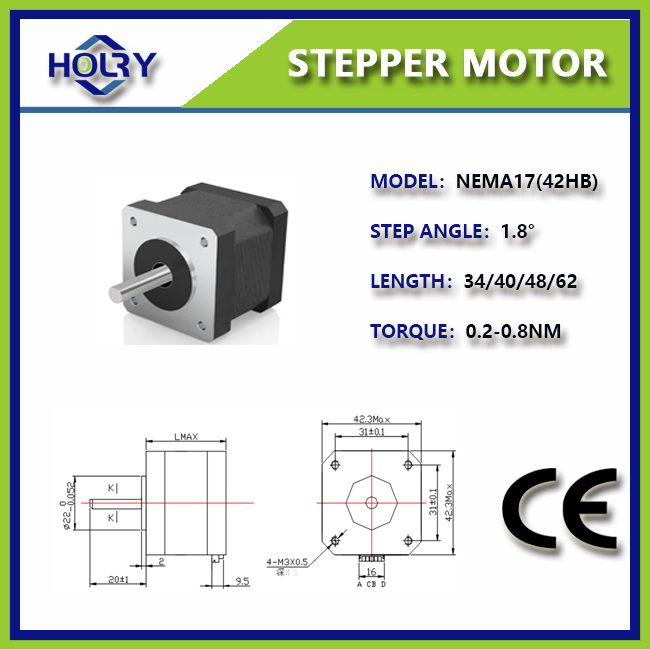

HYBRID STEPPING MOTOR ---42HB 1.8°

---42HB 1.8°

Item | Specifications |

Step Angle | 1.8。 |

Step Angle Accuracy | ±5% (full Step,no load) |

Resistance Accuracy | ±10% |

Inductance Accuracy | ±20% |

Temperature Rise | 80。C Max.(rated current,2 phase on) |

Ambient Temperature | -20。C~+50。C |

Insulation Resistance | 100MΩMin. ,500VDC |

Dielectric Strength | 500VAC for one minute |

Shaft Radial Play | 0.02Max. (450 g-load) |

Shaft Axial Play | 0.08Max. (450 g-load) |

Insulation Class | B(130°) |

Technique Specification

Series Model | Motor Length | Rate Voltage | Rated Current | Phase Resistance | Phase Inductance | Holding Torque | Lead Wire | Rotor Inertia | Motor Weight |

L(mm) | (V) | (A) | (Ω) | (mH) | (Kg.cm) | (NO.) | (g.cm²) | (g) |

42HB34F04AB | 34 | 13.2 | 0.4 | 33 | 45 | 2.4 | 4 | 34 | 200 |

42HB34F08AB | 34 | 4.96 | 0.8 | 6.2 | 10 | 2.4 | 4 | 34 | 200 |

42HB34F105AB | 34 | 2.7 | 1.5 | 1.8 | 2.4 | 2.4 | 4 | 34 | 220 |

42HB40F102AB | 40 | 6.5 | 1.2 | 6 | 13 | 3.0 | 4 | 50 | 220 |

42HB40F107AB | 40 | 2.4 | 1.7 | 1.5 | 2.5 | 3.5 | 4 | 50 | 220 |

42HB40F05AB | 40 | 4.1 | 0.5 | 8 | 15 | 2.6 | 4 | 50 | 250 |

42HB44F05A | 44 | 8.9 | 0.5 | 18 | 23 | 2.9 | 4 | 54 | 250 |

42HB44F1AB | 44 | 8 | 1 | 8 | 16 | 3.5 | 4 | 54 | 250 |

42HB48F04AB | 48 | 8.0 | 0.4 | 20 | 40 | 4.0 | 4 | 68 | 280 |

42HB48F08AB | 48 | 7.2 | 0.8 | 9 | 15 | 4.5 | 4 | 68 | 280 |

42HB48F105AB | 48 | 4.2 | 1.5 | 2.8 | 4.8 | 4.0 | 4 | 68 | 280 |

42HB62F2AB | 62 | 3.2 | 2.0 | 1.6 | 3.0 | 8.0 | 4 | 75 | 320 |

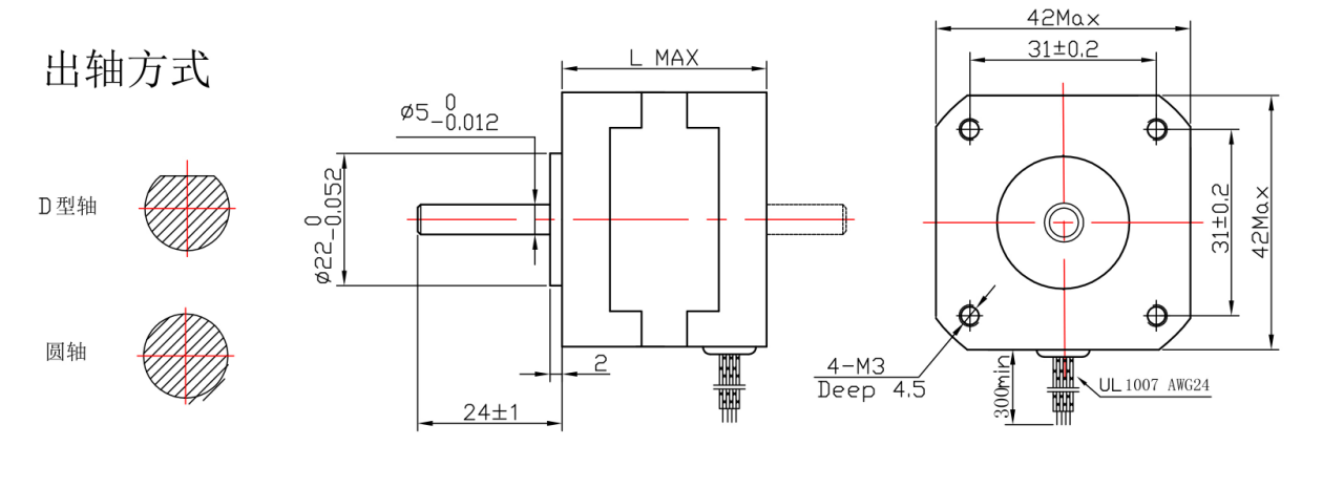

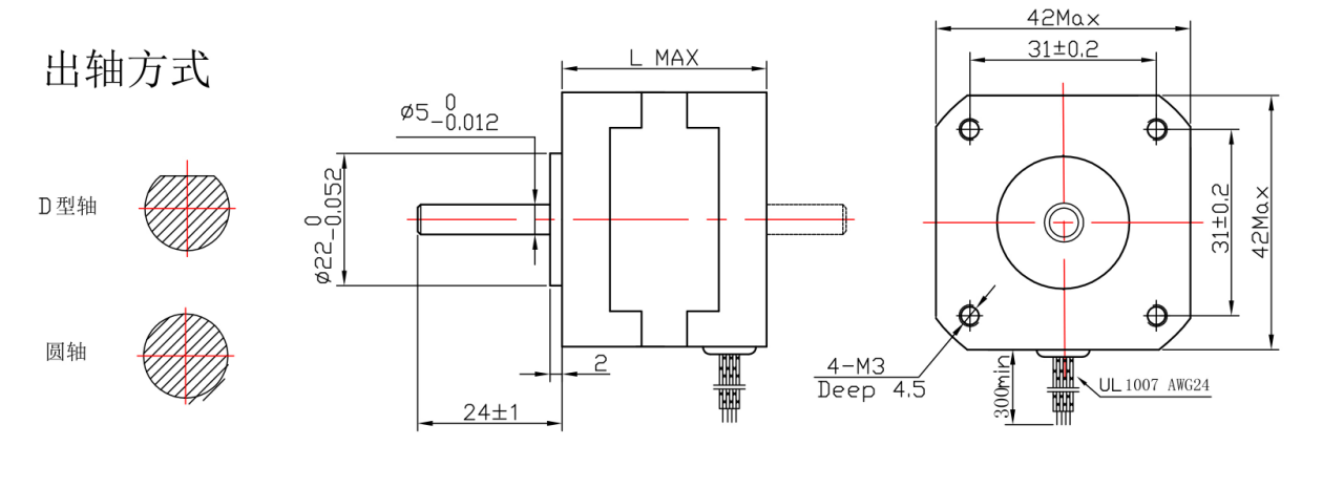

Dimensions

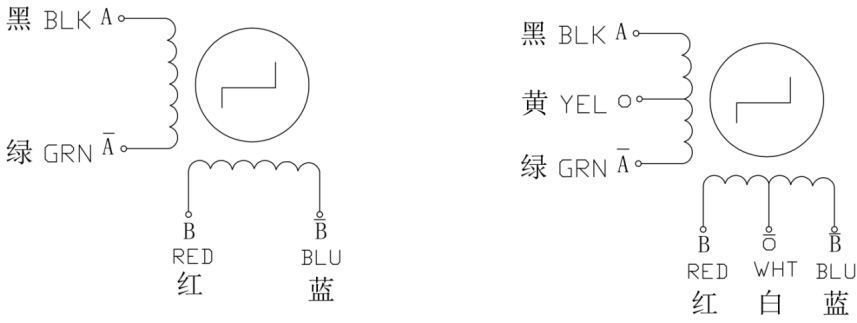

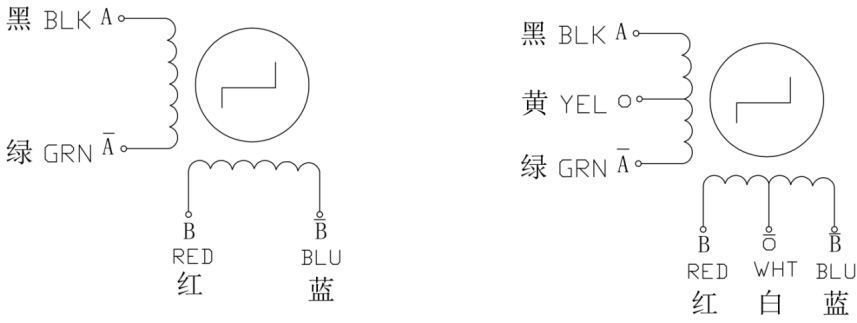

Wiring Diagram

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు

---42HB 1.8°

---42HB 1.8°