DRIVERS---BHD3278

BHD3278 product series is a new generation of three-phase high voltage stepping motor drive, which is designed basing on high-speed DSP + IPM DIGITAL three-phase stepper motor driver and added advanced intelligent control algorithms. Compared with ordinary DSP + IPM model, the new type has improved greatly in many aspects that includes motor adaptation, external signal adaptation, receiving pulse frequency, service life, reliability, stability, and almost without vibration or noise. This new driver is suitable for various types of three-phase hybrid stepping motor with current 7.0A below and outside diameter 57-130mm(torque range: 2NM-60NM). Position accuracy can reach the highest 6000 step/turn. This serious of products have the biggest feature of some types integrating motion control function in internal, supporting touch screen control and data input, and according to customer needs ,pre-installing punch cutting system, automatic feeding and cutting system or customized arbitrarily complex single axis motion control function.

Applications of the drivers

This driver internal integrate digital IO interface of 4 into and 2 out, can meet general motion control requirements. The products are widely used in large and medium-size high resolution digital control equipments of engraving machine, crystal grinding machine, medium-size digital control machine tool, computer embroidery machine, packaging machinery, cutting and feeding system, etc.

Features

Voltage Mode Characteristics of Drivers

●High and low voltage dual mode is suitable for 50V low voltage to 300V high voltage motor.

Pulse characteristics of the drivers

●Single and double pulse dual mode is suitable for pulse + direction mode and CW, CCW double pulse mode.

Drivers torque characteristics

● With large torque, communication control mode etc, it is suitable for application

● integrating motion control function, omitting PLC or motion controller

● It can be controlled by touch screen directly or download parameter.

● Setting 16 gears angle constant torque subdivision, and the highest resolution is 60000 step / turn

The response frequency characteristics of the drivers

● The highest response frequency can be up to 500Kpps, and it is 2.5 times as fast as traditional driver.

● If step pulse stops more than 100ms, coil current will reduce to half of the setting current automatically.

● Photoelectric isolation signal input / output

● 5V, 12V, 24V signal input is compatible, and it’s no need to set current limit resistor external.

● Current effective value of driver is from 1.2A\/ phase to 7.0A\/ phase which can be divided into 16 grades adjustable.

● with single power supply input, voltage range: AC80V-240V

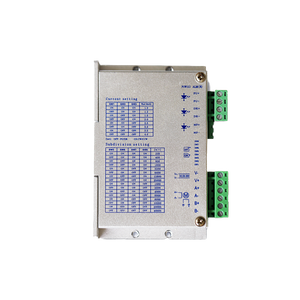

Current Setting

Drive working current is set by DIP-1 end, and running current is normal working output current.

Running current(A) | 1.2 | 1.5 | 2.0 | 2.3 | 2.5 | 3.0 | 3.2 | 3.6 | 4.0 | 4.5 | 5.0 | 5.3 | 5.8 | 6.2 | 6.5 | 7.0 |

D1 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF | ON | ON | ON | ON | ON | ON | ON | ON |

D2 | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON |

D3 | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON |

D4 | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON |

Subdivision setting

Driver subdivision is set by DIP-2 end, and has 16 archives in total. It is set respectively by the first four ones of six dial switches, and the last two are for function setting. Form below is fine fraction (pulse per revolution) for reference.

Fine Fraction | 400 | 500 | 600 | 800 | 1000 | 1200 | 2000 | 3000 | 4000 | 5000 | 6000 | 10000 | 12000 | 20000 | 30000 | 60000 |

D1 | ON | ON | ON | ON | ON | ON | ON | ON | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D2 | ON | ON | ON | ON | OFF | OFF | OFF | OFF | ON | ON | ON | ON | OFF | OFF | OFF | OFF |

D3 | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF | ON | ON | OFF | OFF |

D4 | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF | ON | OFF |

D5 | ON, M type is for the double pulse control model, MA type is for large torque model, MB type is for the serial model, MC type is for the control function, MD is for low voltage motor adaptation mode. |

OFF, M type is for single pulse control mode, MA, MB, MC, MD types are for the normal mode. |

D6 | Automatic detection switch (OFF: receives external pulse, ON: inside of drive runs 30 turns per minute speed. |

Control signal input

All input signals are through the photoelectric isolation, and signal interface has not only 5 v interface but also 12 v / 24 v interface. Users don’t need external current limiting resistor. It supports differential mode input and anode sharing or cathode sharing input.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు