A Choose a CNC spindle that has the RPM, power, and cooling you need for your material. For Wood and Aluminum, a spindle with 24,000 RPM and 1kW power is good.For Steel, RPM between 15,000-18000 and power of 5.6 kW is good for up to 12mm tool size.

Choosing a spindle motor depends on several factors such as the application, the material being machined, the required cutting speed, and the power and torque needed for the operation. Here are some factors to consider when choosing a spindle motor:

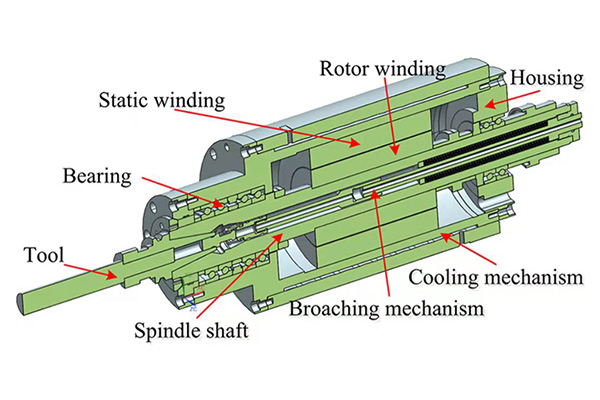

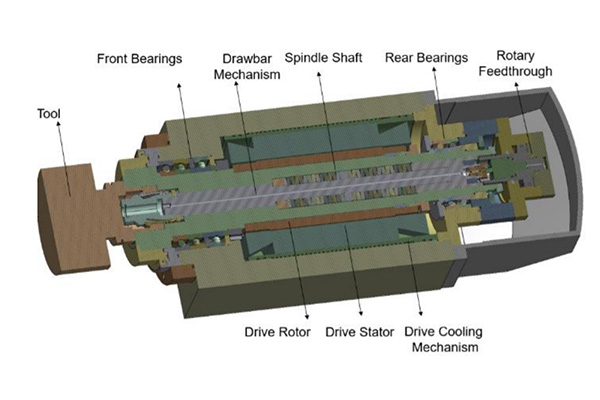

Power and torque: Consider the power and torque requirements for your application, as well as the materials being machined. A more powerful motor will be needed for harder materials or larger workpieces.

Speed: Choose a motor with a speed range that matches your application needs. A higher speed will allow for faster cutting, while a lower speed may be needed for precision work.

Cooling: Consider the cooling requirements for your application. Some spindle motors may require external cooling systems, while others may have built-in cooling mechanisms.

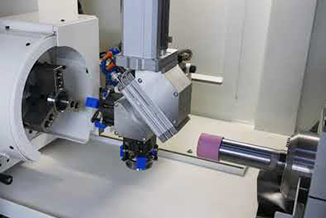

Accuracy: Choose a motor with the required accuracy and precision for your application.Some applications may require high accuracy and repeatability, while others may have looser tolerances.

Noise and vibration: Consider the noise and vibration levels of the motor, as well as any dampening or vibration-absorbing measures that may be needed.

Compatibility: Make sure the spindle motor is compatible with your machine and tooling.Check for any mounting or interface requirements.

Cost: Consider the cost of the spindle motor and any additional equipment or accessories needed.

Overall, it is important to carefully evaluate your application requirements and consult with a knowledgeable spindle motor supplier or spindle motor manufacturer.

HOLRY Motor helps you to select the best spindle motor for your needs. English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు