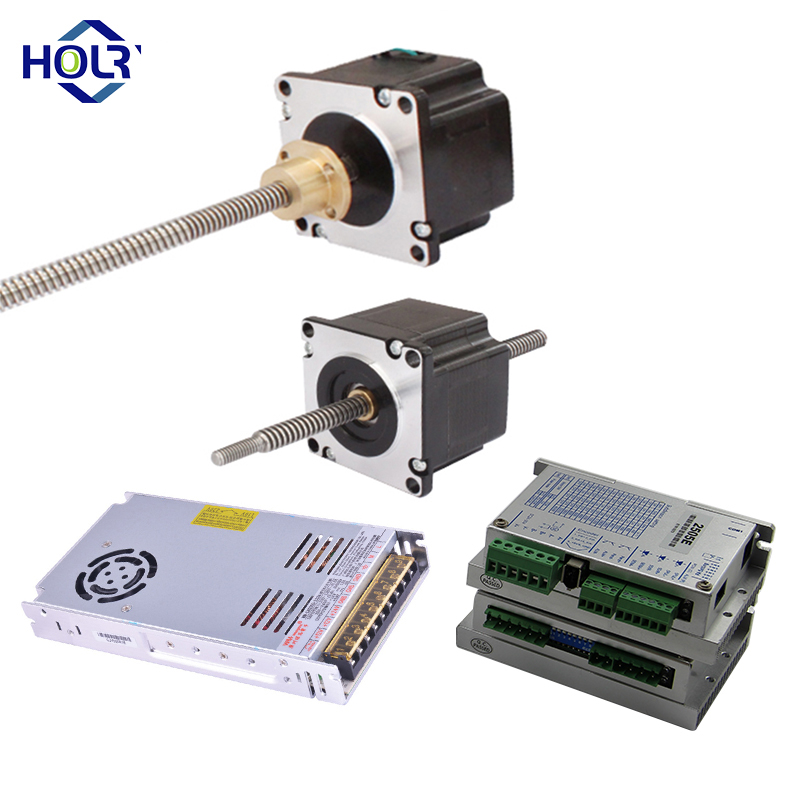

Product Description

The HOLRY' brand of hybrid Stepper Motor Linear Actuators come in five sizes, from 28 mm square to 86 mm square, corresponding to Nema size 11, size 14, size 17, size 23, and size 34. Each size has three to three form factors available - captive, non-captive and an external linear version.

There are over twenty different travels per step available, from. 0001563 inch (.00397 mm) to .003937 inch (1 mm). Microstepping can be used for even finer resolution.

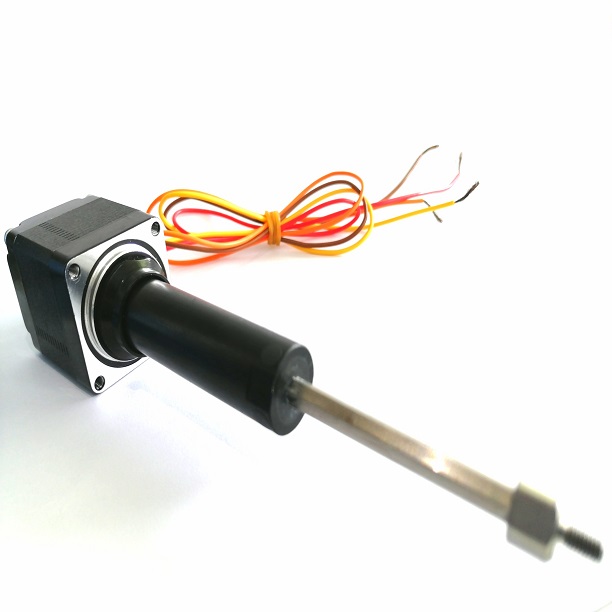

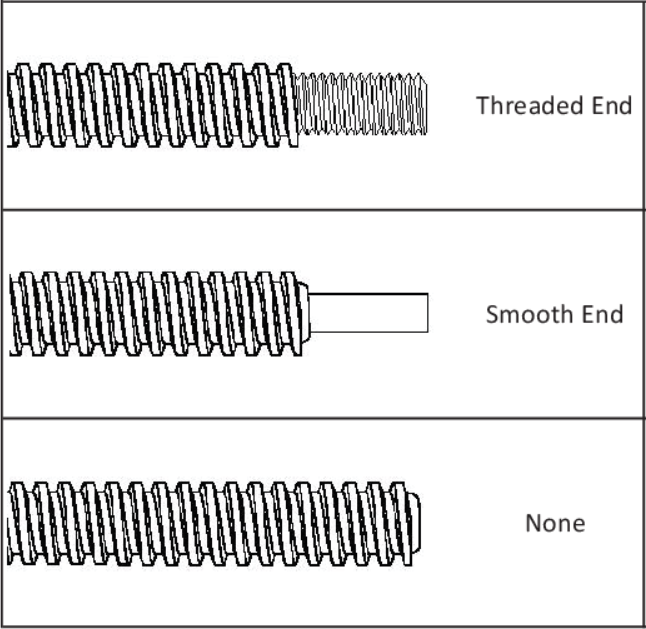

A non-captive lead screw linear actuator is a type of linear actuator that converts rotary motion into linear motion using a lead screw. It is called non-captive because the lead screw is not attached to the motor shaft and can rotate freely, allowing for manual adjustment of the position of the actuator.

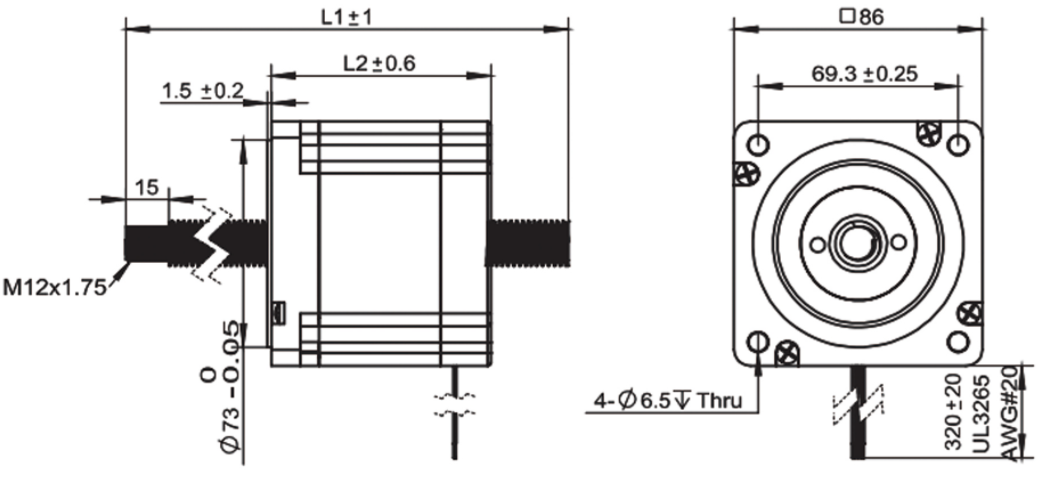

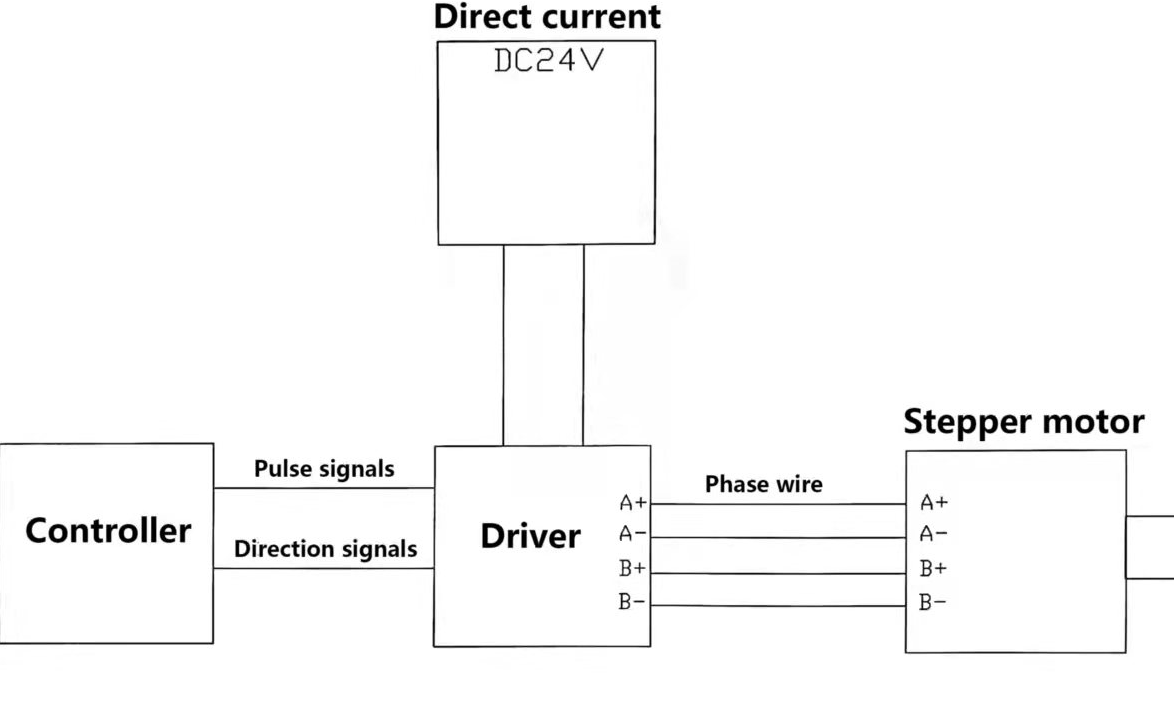

NEMA 34 non-captive lead screw linear actuator is a type of linear actuator that is designed to convert rotational motion into linear motion. The actuator consists of a NEMA 34 stepper motor, a lead screw, and a linear slide.

The NEMA 34 stepper motor is a type of high-torque, low-speed motor that is commonly used in industrial applications. The motor is mounted to the linear slide and is connected to the lead screw through a coupling.

The lead screw is a threaded rod that is designed to translate the rotational motion of the motor into linear motion. The lead screw is typically made of steel or brass and is threaded with a high-pitch thread to maximize the linear travel of the actuator.

The linear slide is a guide rail that supports and guides the linear motion of the actuator. The slide is typically made of aluminum or steel and is designed to provide smooth and precise linear motion.

The term "non-captive" refers to the fact that the lead screw is not physically connected to the motor shaft. This means that the actuator can move freely along the linear slide without rotating the motor.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు