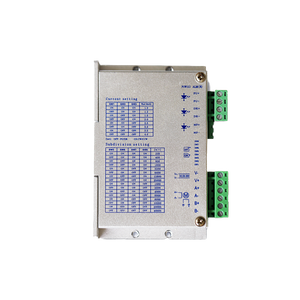

DRIVERS---BHD2178

BHD2178 product series is a new generation of two-phase high voltage hybrid Stepper Mortor (stepping motor) digital driver based on DSP controlled, suitable for various types of two-phase hybrid Stepper Mortor (stepping motor)with current 8.0A below and outside diameter 57-130mm. The internal circuit of the driver is similar to the servo control principle, which can make the motor run smoothly without vibration and noise. The torque of the motor at high speed is far greater than that of similar products in the market, and the positioning accuracy can reach up to 40000 step / turn. The products are widely used in woodworking engraving machine, medium-sized CNC machine tools, computer embroidery machine, packaging machinery.

Technical characteristics

Setting 16 gears angle constant torque subdivision, and the highest resolution is 40000 step / turn

The highest response frequency can be up to 500Kpps

If step pulse stops more than 1.5s, coil current will reduce to half of the setting current automatically.

Photoelectric isolation signal input / output

Current effective value of driver is from 0.5A/ phase to 8.0A/ phase which can be divided into 16 grades adjustable.

with single power supply input, voltage range: AC40V-110V

Phase memory function (Note: after the input stops for more than 3 seconds, the driver will automatically remember the motor phase at that time. When the power is turned on again or the MF signal changes from low level to high level, the driver will automatically restore the motor phase).

Current setting

The working current of the driver is set by D1-D4 terminals, and the operating current is the normal working output current setting switch (see the table below for details)

Running current(A) | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 |

D1 | OFF | OFF | OFF | OFF | OFF | OFF | OFF | OFF |

D2 | OFF | OFF | OFF | OFF | ON | ON | ON | ON |

D3 | OFF | OFF | ON | ON | OFF | OFF | ON | ON |

D4 | OFF | ON | OFF | ON | OFF | ON | OFF | ON |

Running current(A) | 4.5 | 5.0 | 5.5 | 6.0 | 6.5 | 7.0 | 7.5 | 8.0 |

D1 | ON | ON | ON | ON | ON | ON | ON | ON |

D2 | OFF | OFF | OFF | OFF | ON | ON | ON | ON |

D3 | OFF | OFF | ON | ON | OFF | OFF | ON | ON |

D4 | OFF | ON | OFF | ON | OFF | ON | OFF | ON |

Pin function description

Port definition | No. of connector pin | Marking symbol | Function | Note |

DB15 | 1 | 5PU+ | Positive input end of photoelectric isolated I/O | Connected to + 5V power supply, + 5V - + 24V can be driven, higher than + 5V need to connect current limiting resistor |

2 | PU- | DP9= OFF, PU is stepping pulse signal | The falling edge is valid. When the pulse changes from high to low, the motor moves one step, and the input resistance is 220 Ω. Requirements: low level 0-0.5v, high level 4-5v, pulse width > 2.5 μ S |

DP9=ON, PU is positive phase of stepping pulse signal |

3 | 5DR+ | Positive input end of photoelectric isolated I/O | Connected to + 5V power supply, + 5V - + 24V can be driven, higher than + 5V need to connect current limiting resistor |

4 | DR- | DP9= OFF, DR is direction control signal | Used to change the direction of the motor. Input resistance 220 Ω, requirements: low level 0-0.5v, high level 4-5v, pulse width > 2.5 μ S |

DP9=ON, DR is negative direction of stepping pulse signal |

7 | 5MF+ | Positive input end of photoelectric isolated I/O | Connected to + 5V power supply, + 5V - + 24V can be driven, higher than + 5V need to connect current limiting resistor |

8 | MF- | Motor release signal | When effective (low level), turn off the motor coil current, the driver stops working, and the motor is in the release state. |

9 | ALM+ | Positive fault output signal end of Photoelectric isolated I/O | When the driver has over-current or overheat fault, the driver outputs fault signal, which is valid (low level) |

10 | ALM- | Negative fault output signal end of Photoelectric isolated I/O |

|

11 | RDY+ | The driver is ready to output the signal to the positive end of photoelectric isolated I/O | The driver status is normal, and the signal is valid when it is ready to receive the driver signal (low level) |

12 | RDY- | The driver is ready to output the signal to the negative end of photoelectric isolated I/O |

|

13 | 24PU+ | Positive input end of photoelectric isolated I/O | +24 V driveable |

14 | 24DR+ | Positive input end of photoelectric isolated I/O | +24 V driveable |

15 | 24MF+ | Positive input end of photoelectric isolated I/O | +24 V driveable |

Motor and power terminal | 1、2 | L1、L2 | Power supply | Power:AC40-110V |

3 | A+ | Motor wiring |

|

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు