80 Integrated Brushless Motor

Built-in Drive | Easy Control |Steady Perform

400W

80 Integrated Brushless Motor Features

| Integrated Drive | Compact, User-Friendly, Easy to Wire |

| High Speed | Speed Range: 150-3000 rpm |

| Long service Life | 30,000+ Hours Lifespan. Minimal Maintenance (Dusting Only) |

| Low Noise | Low Friction, Low Noise, Steady and Smooth Operation |

Usage Guidelines:

Ensure a clean, dry, and ventilated environment.Set acceleration/deceleration braking time between0.3-1.5 seconds. A longer setting within this range protects the motor and extends its lifespan.

80 Integrated Brushless Motor Application

Brushless motors are widely used in electronic manufacturing,medical devices, industrial robots, automation equipment, etc.

80 Integrated Brushless Motor Parameters

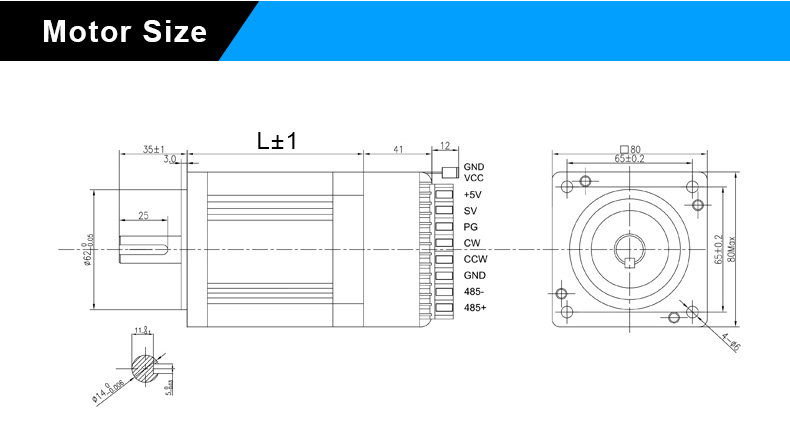

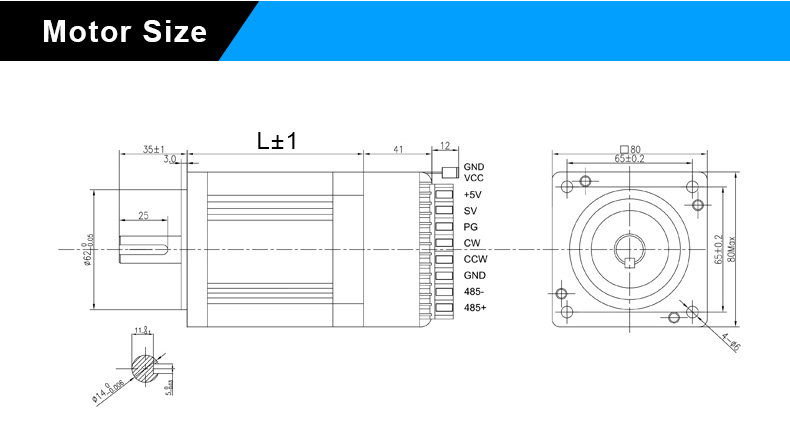

| MODEL | Motor Length (L) mm | Shaft Longth (mm) | Shaft diameter (mm) | Rated Voltage (VDC) | Rated Power (w) | Rated Speod (RPM) | Rated Torque (N.m) | Rotor Inertia (Kg.cm2) | Motor Weight (K9) |

| 80BLDC100 | 60 | 32 | 14 | 24 - 48 | 400 | 3000 | 1.27 | 53 | 2.5 |

| POWER WIRING | CONTROL WIRING |

| GND | VCC | +5V | SV | PG

| CW | CCW | GND

| 485- | 485+ |

| DC- | 24V+ | 5V Speed Regulation Voltage Output | Speed Regulation Voltage Input Terminal | Motor speed pulse output | Motor Fornard | Motor Reverse | Public side | RS485- | RS485+ |

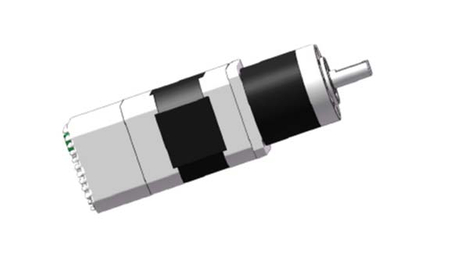

80 Integrated Brushless Motor Display

80 Integrated Brushless Motor FAQ

What is an 80 Integrated Brushless Motor?

80 Integrated Brushless Motor is a compact brushless DC (BLDC) motor with an 80mm flange size that combines the motor, electronic driver/controller, and often an encoder (and sometimes a brake) into a single unit. This all-in-one design simplifies wiring and installation compared to separate components.

What does "integrated" mean in this motor?

"Integrated" means the motor includes a built-in driver (controller) and often feedback devices like an encoder. This eliminates the need for an external controller, reducing system complexity, cabling, and space requirements while enabling direct control via inputs like analog signals, pulse/direction, or fieldbus protocols.

What are the main advantages of an integrated brushless motor over a standard brushless motor?

Key advantages include compact size, easier installation, reduced wiring errors, lower overall system cost, improved reliability (fewer connections), and better EMI performance. It also offers servo-like precision with the durability of brushless technology.

What are the typical specifications for an 80mm integrated brushless motor?

Common specs include: power range 300W–1000W, rated torque 0.9–3Nm (up to higher with gearbox), speed 3000–6000rpm, voltage 24V–48V DC, IP65 protection, and optional absolute encoder or holding brake. Exact values vary by manufacturer and model.

What control methods does it support?

Most models support multiple modes: analog/digital inputs, pulse/direction (for positioning), fieldbus (e.g., CANopen, Modbus, EtherCAT), or clock/direction. This flexibility allows easy integration into various automation systems.

What applications is the 80 Integrated Brushless Motor suitable for?

It is widely used in industrial automation, robotics (e.g., robotic arms), AGV/AMR vehicles, medical equipment, pumps/valves, conveyor systems, and precision machinery where space is limited and high performance is required.

Why choose a brushless design over a brushed motor?

Brushless motors offer higher efficiency (up to 90%+), longer lifespan (no brush wear), lower noise/vibration, reduced maintenance, better speed/torque control, and suitability for harsh environments—making them far superior for modern applications.

Can it be customized?

Yes, many manufacturers offer customization options such as voltage ratings, speed/torque curves, shaft modifications, integrated gearboxes, encoders (incremental or absolute), brakes, connectors, and IP ratings to match specific requirements.

What is the typical protection rating and operating environment?

Most 80mm integrated models are rated IP65 (dust-tight and water-resistant), allowing use in harsh industrial environments with dust, moisture, or splashes. Operating temperatures usually range from -20°C to +50°C.

How does it compare to a traditional servo motor?

It provides servo-level precision and control (especially with encoder feedback) at a lower cost and with greater durability than AC servos. While not always as high-end as full servo systems, it matches many AC servo flanges (e.g., 80mm) and power levels for cost-effective alternatives.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు