86 Integrated Brushless Motor

Built-in Drive | Easy Control |Steady Perform

400W

86 Integrated Brushless Motor Features

| Integrated Drive | Compact, User-Friendly, Easy to Wire |

| High Speed | Speed Range: 150-3000 rpm |

| Long service Life | 30,000+ Hours Lifespan. Minimal Maintenance (Dusting Only) |

| Low Noise | Low Friction, Low Noise, Steady and Smooth Operation |

Usage Guidelines:

Ensure a clean, dry, and ventilated environment.Set acceleration/deceleration braking time between 0.3-1.5 seconds. longer setting within this range protects the motor and extends its lifespan.

86 Integrated Brushless Motor Application

Brushless motors are widely used in electronic manufacturing,medical devices, industrial robots, automation equipment, etc.

86 Integrated Brushless Motor Parameters

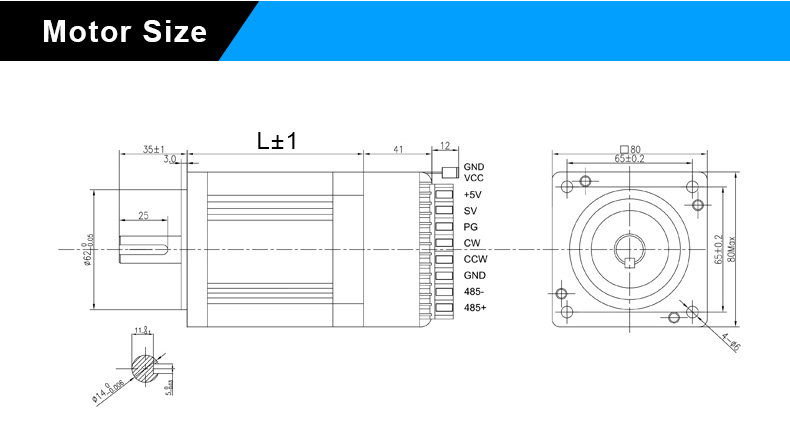

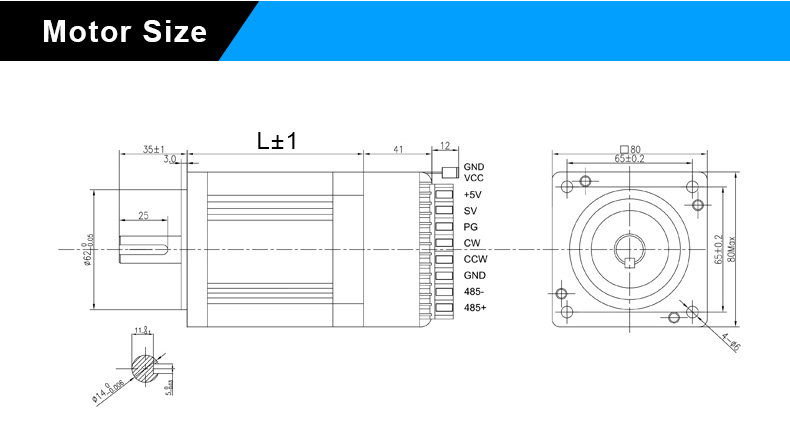

| MODEL | Motor Length (L) mm | Shaft Longth (mm) | Shaft diameter (mm) | Rated Voltage (VDC) | Rated Power (w) | Rated Speod (RPM) | Rated Torque (N.m) | Rotor Inertia (Kg.cm2) | Motor Weight (K9) |

| 86BLDC 60 | 60 | 32 | 14 | 24 - 48 | 100 | 3000 | 0.32 | 100 | 2.2 |

| 86BLDC 70 | 70 | 32 | 14 | 24 - 48 | 200 | 3000 | 0.65 | 120 | 2.5 |

| 86BLDC 80 | 80 | 32 | 14 | 24 - 48 | 300 | 3000 | 0.65 | 120 | 2.5 |

| 86BLDC 90 | 90

| 32 | 14 | 24 - 48 | 400 | 3000 | 0.65 | 120 | 2.5 |

| POWER WIRING | CONTROL WIRING |

| GND | VCC | +5V | SV | PG

| CW | CCW | GND

| 485- | 485+ |

| DC- | 24V+ | 5V Speed Regulation Voltage Output | Speed Regulation Voltage Input Terminal | Motor speed pulse output | Motor Fornard | Motor Reverse | Public side | RS485- | RS485+ |

86 Integrated Brushless Motor Display

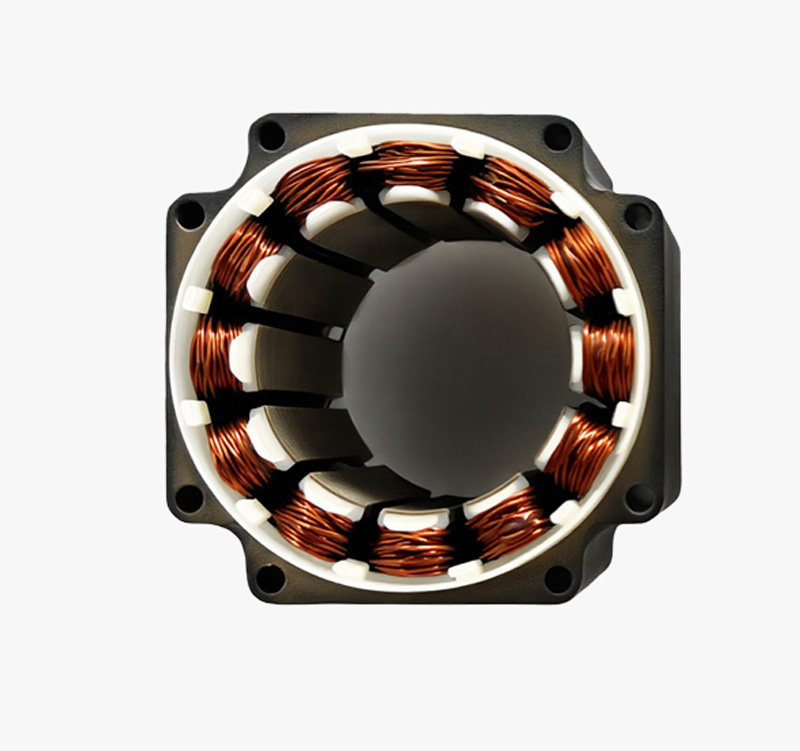

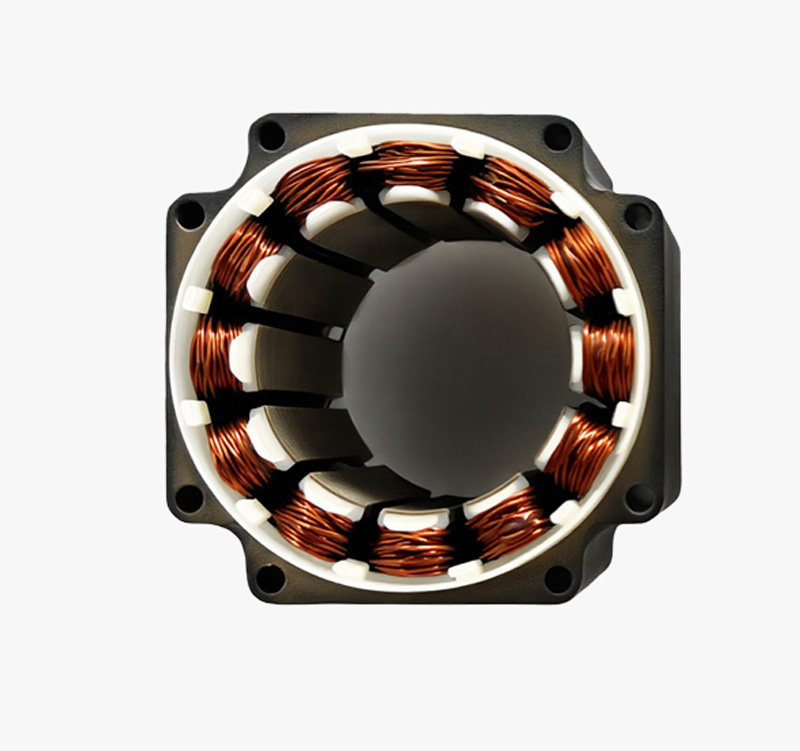

86 Integrated Brushless Motor Motor Coil

Our motors use pure enamel-insulated copper wire and advanced wind-ing technology. The precise, uniform arrangement of the copper wire re-sults in lower temperature rise, preventing deformation and noise duringlong-term operation, thereby extending the motor's service life.

HOLRY Integrated Steppers Supplier FAQ

We start production right after you order and ship it out fast. We'l choose the best carrierfor your location and order size.Need a specific shipper? Just tell us when you order.

Standard Products: 1-year warranty, Return unused itemin original condition (unused, intheir original packaging,undamaged, and with all labels intact) within 7 davs foa fullrefund,or exchange within 30 days. You cover return shipping.Custom Products:1-year warranty on defects only. No retums or exchanges. Buyersare responsible for selection errors.

Customer Service & Suport

1.Quality First: We contrl quality from the start.

2.Quick order processingfast dispatching and worldwide delivery.

3.Full Support: Drawingsand custom solutions available for all motors

86 Integrated Brushless Motor FAQ

What is an 86 integrated brushless motor?

86 integrated brushless motor refers to a brushless DC motor (BLDC) with a flange size of 86mm × 86mm (equivalent to NEMA 34 standard), featuring a built-in driver and control chip for an all-in-one design (such as the 86IBL series). It combines the motor, driver, and high-performance control technology, offering compact size, simple wiring, and is suitable for industrial automation control applications.

What is the difference between an 86 integrated brushless motor and a standard brushless motor?

Standard brushless motor requires an external driver, whereas the integrated motor has the driver built into the motor body. This reduces external wiring, saves space, minimizes interference, and provides comprehensive protection functions such as overvoltage and overcurrent, making installation and use more convenient.

What is the power range of the 86 integrated brushless motor?

Common power ratings range from 100W to 400W (e.g., 100W, 200W, 400W models), with some extensions up to 750W, depending on the specific model and voltage configuration.

What are the supported voltages and speeds?

Common voltages are 24VDC or 48VDC, with rated speeds typically at 1500RPM or 3000RPM. It supports high-speed operation with low vibration and low noise.

What are the advantages of the 86 integrated brushless motor?

High integration, compact size, simple wiring, comprehensive protection (overvoltage, undervoltage, overcurrent, peak current, Hall signal faults, etc.); adopts advanced PWM technology for smooth high-speed operation; low vibration, low noise, high stability, and strong reliability.

How to control the speed and direction of the 86 integrated brushless motor?

Control is achieved through input signals to the built-in driver (such as PWM and direction signals) or via RS485 communication (supporting standard Modbus RTU protocol). It supports forward/reverse rotation, speed adjustment, and PID dual closed-loop regulation.

Does it support closed-loop control?

Some models support Hall sensor feedback for closed-loop control, ensuring precise speed and position; advanced models can be extended with encoders for more accurate servo control.

Can it be customized?

Yes, many manufacturers offer customization options such as voltage ratings, speed/torque curves, shaft modifications, integrated gearboxes, encoders (incremental or absolute), brakes, connectors, and IP ratings to match specific requirements.

What applications are suitable for the 86 integrated brushless motor?

Widely used in industrial automation, robotics, medical equipment, logistics and warehousing, CNC equipment, automated production lines, and other scenarios requiring high reliability and compact installation.

How is the heat generation and noise during motor operation?

Thanks to the brushless design and efficient PWM control, it has low heat generation, low noise, and minimal vibration, making it suitable for long-term continuous operation.

What are the installation and maintenance precautions?

During installation, pay attention to the shaft diameter (typically 14mm) and flange mounting; avoid overload operation; regularly check wiring and heat dissipation; the built-in protection functions can provide alarms, maintenance is simple, and no carbon brush replacement is required.

English

Русский

العربية

Français

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

Dansk

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

සිංහල

Azərbaycan dili

Euskara

Беларуская мова

Български

guarani

Kreyòl ayisyen

Kurdî

Lietuvių

Македонски

తెలుగు